Conveyance

Storage

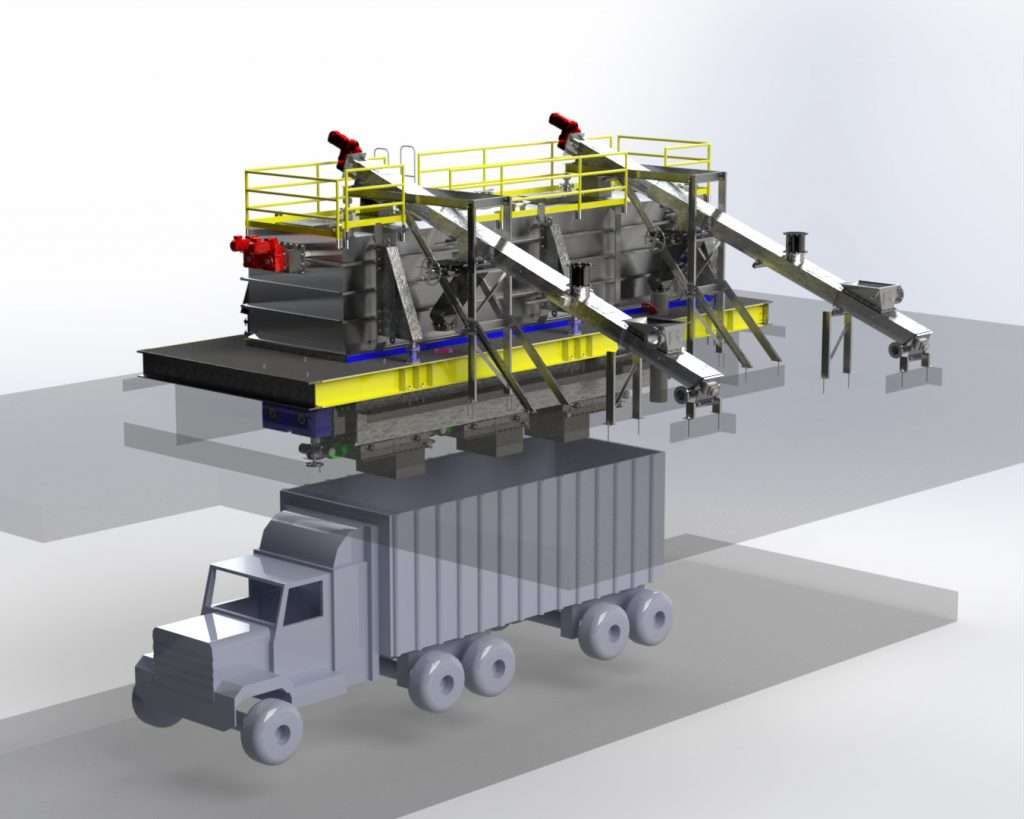

Systems

Solids Receival

JMS Solids Receival Systems provide temporary storage of solids received from foreign sources. Trucks or front-end loaders deposit solids into our systems before conveyance to downstream equipment for further processing. Typically installed at ground level for ease of filling, JMS Solids Receival Systems meter solids at controlled rates through Bio-LIVEBOTTOMs, Bio-FRAMEs, Bio-SCREWs, and Bio-GATEs.

Solids Storage

JMS offers a complete line of material handling and storage solutions designed to fit precise applications. We carefully consider all aspects of an application before selecting the most appropriate components and equipment to complete all Bio-HANDLING systems.

Dry Solids

JMS dried biosolids storage systems act as the first line of defense against fire/explosions. Our rigorous product standards ensure excellent handling of dried sewage sludge, accounting for combustion and self-heating properties and meeting NFPA (National Fire Protection Association) requirements for transport and storage.

Solids Loadout

JMS Solids Loadout systems provide easy conveyance and even distribution of material into truck beds or containers. Typically fed from a Bio-HOPPER hopper, Bio-SCREW or Bio-BELT conveyor(s), or directly from dewatering equipment, JMS Solids Loadout Systems can be automated to discharge material via Bio-GATE slide gates or Bio-DIVERTER diverter valves located at multiple discharge points.

Aftermarket