Drinking Water

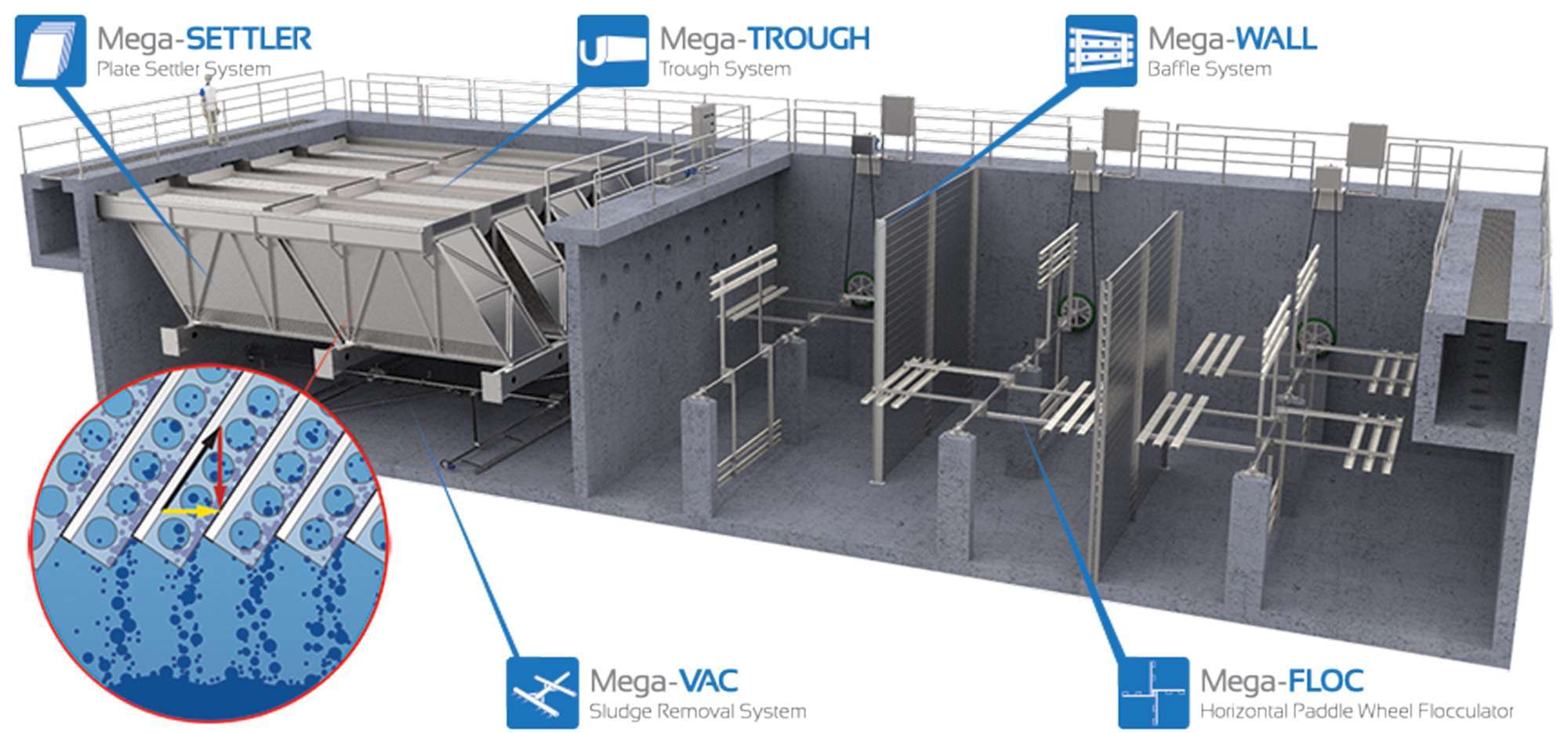

Inclined plate settlers are an enhanced, high-rate sedimentation technology that has been applied to water treatment for more than 100 years. With decades of experience and field data, the JMS Mega-SETTLER (Plate Settler System) has developed new technological approaches which keep moving the market forward.

Increasingly, treatment plants are asked to do more and the need for maximizing what’s available has never been more evident. The Mega-SETTLER (Plate Settler System) for Drinking Water processes billions of gallons of water every day. This system is used for new high-rate water treatment sedimentation basins, to retrofit existing conventional sedimentation basins into high-rate sedimentation basins, and for wash water and backwash treatment.

The Mega-SETTLER (Plate Settler System) for Drinking Water design program calculates the effective projected horizontal surface area required for a given design flow, while optimizing other variables critical to the process. The result is the most efficient approach possible to maximizing the treatment capacity of the basin and improving effluent quality.

The system can suit any basin geometry. This approach can dramatically reduce the footprint of a conventional sedimentation basin, often by as much as 50 to 90%. It can also significantly increase the treatment capacity of existing basins while improving effluent quality. Compared to similar output sedimentation basins without plate settlers, the Mega-SETTLER requires a much smaller footprint, performs consistently better, absorbs turbidity spikes, and is overall a more reliable and visually appealing choice. Plate settlers cost less when all capital, construction and operational costs are factored in over the life of the system.

The Mega-SETTLER (Plate Settler System) for Drinking Water is certified to ANSI/NSF-61 standards and constructed of 100% stainless steel for superior longevity. It’s the strongest plate settler system available and the only one that can safely support the weight of operators for wash-down and service.

Key features

- Designed and fabricated in the USA with 100% stainless steel

- JMS-patented TFCA™ (Top Flow Control Angle provides even laminar flow and reduced clogging

- 2VNP™ adjustable V-notch weirs fine-tune water elevations to accommodate fluctuations in flow

- Dual side-loaded effluent troughs allow high visibility and access to plates

- High-quality effluent performance

- Strongest plate settler on the market*

- Certified to ANSI/NSF-61 standards

*Independent third-party ASTM standards testing

Related Videos

Success Story

JMS has worked with the SJWD Lyman WTP over the years to supply multiple pieces of equipment. This included supply of JMS Mega-SETTLER (Plate Settler System) and Mega-FLOC (Horizontal Paddle Wheel Flocculator). The new equipment has helped the plant meet the needs of the growing population in the area by increasing the plant capacity from 14 million gallons/day (MGD) to 18 MGD. Plant personnel have fully optimized mechanical and chemical systems for low turbidity water going to downstream membranes. Repeat business is always a compliment, and JMS is happy to be one of the chosen suppliers for this plant.