Solids Receival System

Lenoir, North Carolina

Designing a safe and seamless biosolids management system is vital for human health and environmental safety. Although processes vary, all management systems must include seamless transportation and storage.

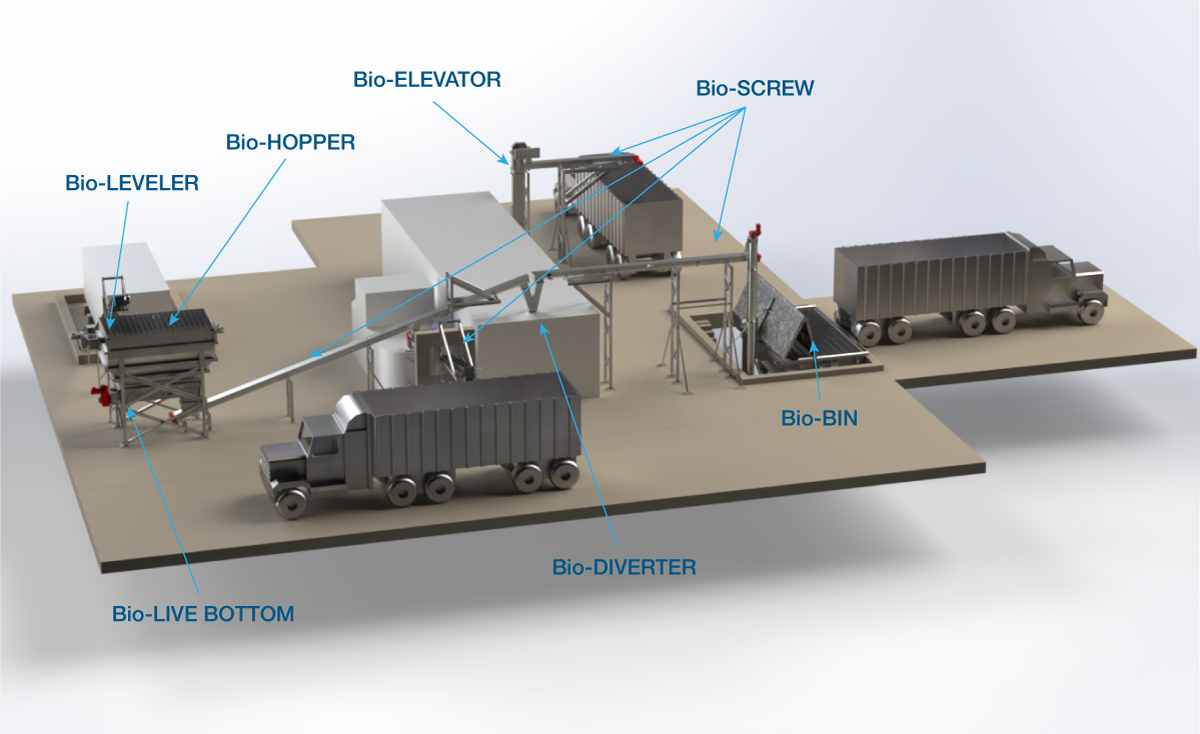

JMS Solids Receival Systems provide temporary storage of solids received from foreign sources. Trucks or front-end loaders deposit solids into our systems before conveyance to downstream equipment such as dyers, incinerators or THP equipment, for further processing. Typically installed at ground level for ease of filling, JMS Solids Receival Systems meter solids at controlled rates through Bio-LIVEBOTTOMs, Bio-FRAMEs, Bio-SCREWs, and Bio-GATEs.

Optimized to prevent material plugging and bridging while offering even distribution, JMS receival systems empower regional processing facilities to fully utilize receival capacity, offering quick returns on investment (ROI).

Solids Receival Systems Options

- Rectangular metered-end discharge bin with Bio-LIVEBOTTOM screws or sliding frames

- Circular bottom discharge Bio-HOPPER with Bio-LIVEBOTTOM screws

- Actuated retractable truck cover

- Hopper load cells

- Leveling screws

- Shafted or shaftless Bio-SCREW (Screw Conveyors)

- Bio-BELT (Belt Conveyors) with belt scales

- Bio-LEVEL sensors

- Bio-GATE (Slide Gates)

- Bio-STRUCTURAL (Structural Platforms/Walkways)

- Bio-CONTROLS (Control Panels)

Key features

- Custom designed for each unique application

- Various size and capacity options depending on demand, and footprint restraints

- Retractable covers for personnel safety, odor control, and weather protection

- Minimal maintenance required with easily sourced replacement components

- Complete integrated system with other JMS offered Bio-HANDLING equipment