Paddle wheel flocculators could be compared to the movement of the paddle wheel boat. Their slow speed and low shear mixing method is well suited for the water treatment processes municipalities require. With our introduction of stainless steel sprockets and bearing housings, no painted components are required in the basin.

JMS has invested 60 years of experience in creating a flocculator design program that optimizes the system layout for unparalleled performance. The JMS Mega-FLOC design program calculates all critical design parameters simultaneously to provide instant feedback. Over the past decade, JMS has provided thousands of flocculator designs/layouts optimized for engineers and municipalities.

Having sold more horizontal flocculators in the U.S. than any other supplier, JMS has the expertise to determine optimal gear motor horsepower requirements using the desired velocity gradient, system efficiencies and safety factors. JMS can accommodate a wide range of needs with multiple drive options.

An engineered chain, typically H-78 pitch, and manufactured from 400 series stainless steel.

- Uses an innovative self-lubricating bearing grade composite and exhibits up to 15X longer life than liners using traditional materials

- Stainless steel bearing housing

- Flexible, stainless steel Mega-COUPLING, which absorbs small amounts of misalignment and extends the life of the stuffing box and bearings

- Also known as T-630 stainless steel, 17-4 ph solid shafting at bearing locations has a much higher Rockwell Hardness and resists abrasion much better than 300-series stainless steel

- Stainless steel sprocket hubs are more resistant to rust, barnacles and corrosion than traditional painted cast iron

- Stuffing box exhibits design perfection and performance thanks to JMS’s unparalleled experience

- Full-dip passivation

Key features

- High quality floc particle with compliant tip speed below 3ft/s

- Best value per million gallons per day (MGD)

- One drive can power multiple paddle reels for efficiency

- Stainless steel bearing housings and sprockets

- Certified to ANSI/NSF-61 standards

Related Videos

Success Story

The Ed Love Water Treatment Facility is one of two water plants owned and operated by the City of Tuscaloosa, AL. Tuscaloosa is in west-central AL, and is home to more than 95,000 residents and a number of businesses. This facility, built in 1976, sits near Lake Tuscaloosa, the source for incoming water.

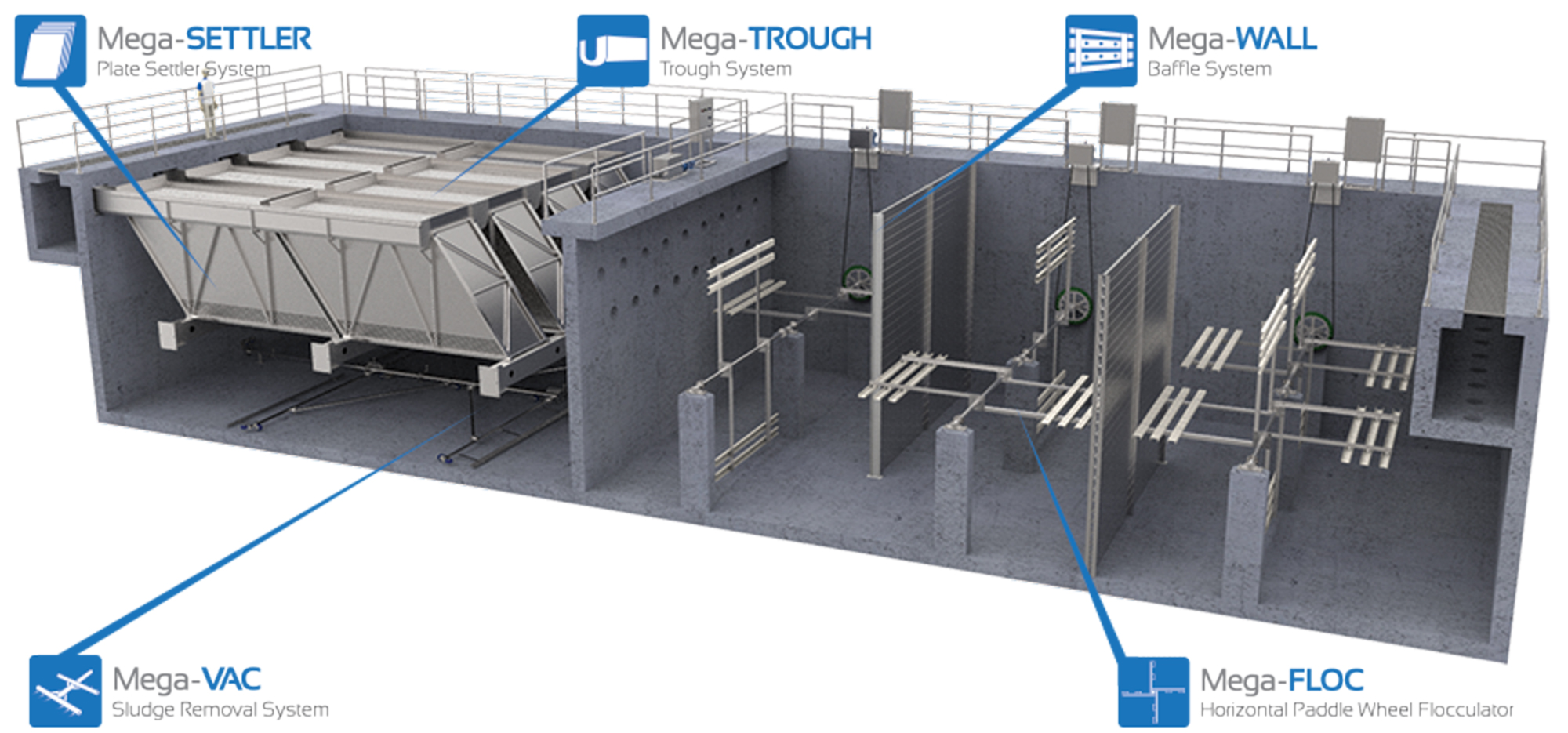

In response to population growth, the city embarked on a program to increase water production capacity, including upgrades at the Ed Love Plant, and a new plant to serve the area. At the former, old paddle style flocculators, with multiple reels powered by a single motor, were in dire need of replacement. Working with Almon Assoc., a highly regarded local engineering firm, JMS specialists proposed Mega-FLOC (Horizontal Paddle Wheel Floccculator) with each flocculator reel on a single drive to give the plant the flexibility they desired.

Four years later, the installation of JMS Mega-FLOC (Horizontal Paddle Wheel Flocculator) is considered a great success. Mr. Chris Jarrell, a 26 year veteran of the facility, praises the new equipment as more efficient with less maintenance requirements. JMS ability to customize the system, has surpassed their needs in terms of process control, and overall flexibility.

The JMS Way

#13

Create win/win solutions.

It’s a two-way street. Learn to think from others’ perspective. Discover what they need and find a way to help them meet those needs while also fulfilling your own. Win/win solutions are always more effective and longer lasting than win/lose situations.