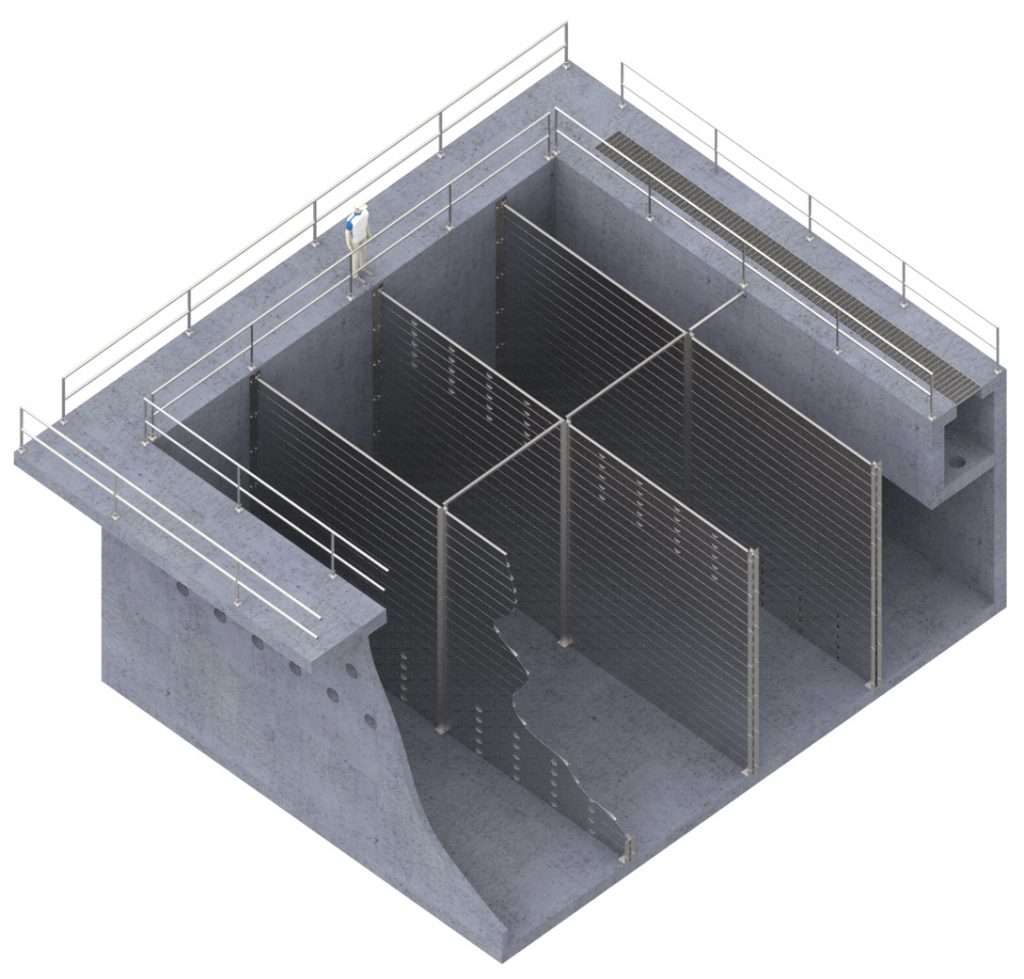

The JMS Mega-WALL Baffle System baffles and weirs are used in flocculators, aerators, clarifiers and other tanks to improve flow patterns and/or retention time, increasing system efficiency. The baffles are effective at preventing channeling and minimizing short circuiting.

Designed for flexibility, the Mega-WALL Baffle System can be used in circular or rectangular basins or tanks and in concrete or steel structures. Depending on end use needs, flow options include over-under, serpentine, around and through with ported baffles.

All components are manufactured using stainless steel with profile design for added strength. Slotted stacking system support frames are fully welded and allow for ease in sliding the panels securely into place. Plate length can be customized up to 12 feet.

NSF-61 certified, Mega-WALL baffles are used in a variety of applications, with customized solutions engineered by experienced JMS designers. The installation can include doors to allow easy access to basin areas for better cleaning.

Common Applications for the Mega-WALL Baffle System

- Water Treatment: Flocculation basins, clarifiers

- Wastewater Treatment: Flocculation basins, clarifiers

- Industrial: Water tanks, clarifiers

Key features

- Increased settling time results in reduced TSS (total suspended solids)

- Flexible modular design

- Quick and easy installation

- Extended contact time for greater process control

- Installation fast and hassle-free

- Certified to ANSI/NSF-61 standards

The JMS Way

#26

Keep things fun.

While our passion for excellence is real, remember that the world has bigger problems than the daily challenges that make up our work. Don’t take things personally or take yourself too seriously. Laugh every day.