JMS delivered a dried biosolids Bio-HANDLING (Material Handling Systems) conveying, storage, and load-out system for a project on the east coast. This renewable energy biosolids facility is designed to reduce energy consumption at the wastewater treatment plant and produce Class A biosolids. Extracted biosolids from the wastewater treatment process are transferred to the renewable energy process where it is dewatered and dried providing fuel to supplement the drying process, and dramatically reducing the amounts of material to be handled.

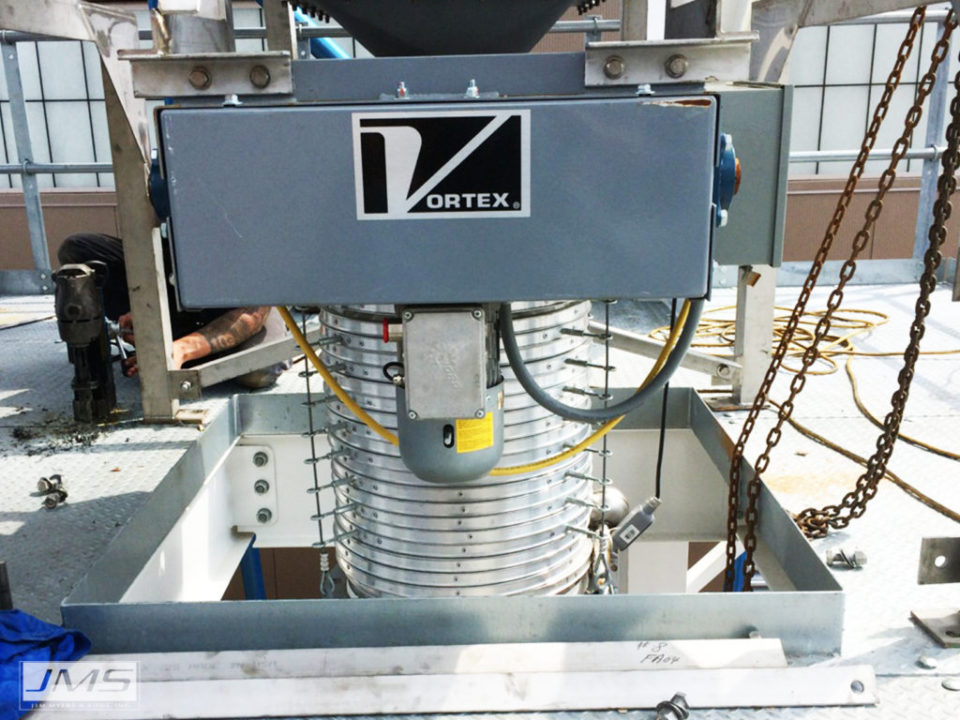

JMS equipment receives the high temperature dried biosolids for transfer to a 40 foot tall JMS silo for off-loading to trucks. This silo is fitted with both thermocouples to strictly monitor the temperature through PLC control and a CO monitoring system. Load cells on the silo measure material for unloading through a slide gate valve and on to a JMS screw conveyor with dust collection system. Material exits via one of three discharge slide gates for equal distribution on the truck.

Special accommodations were made by JMS for safety and efficient operation. A dust collection system was fitted on both the screw conveyor and each load-out spout. Spouts extend/retract as the truck load level changes to further minimize dusting. With the help of JMS, this plant has created a fully automated truck load-out facility that is monitored remotely by the SCADA system.