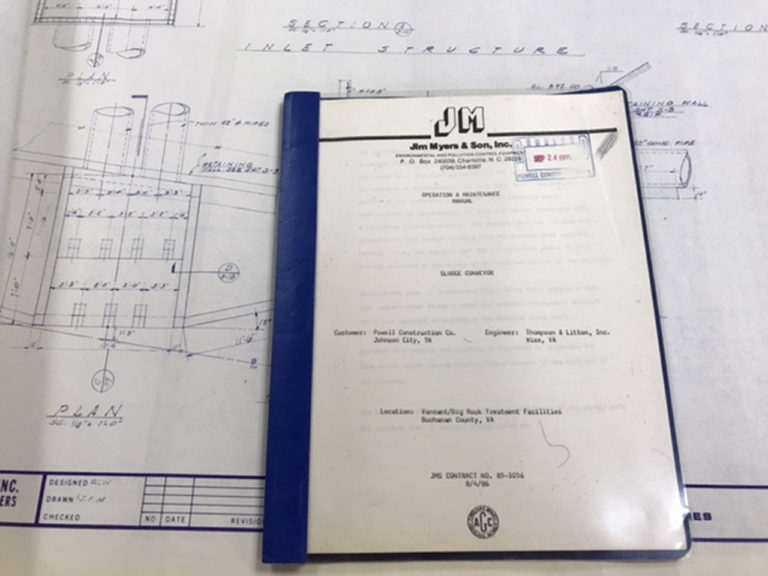

Both the JMS Bio-BELT (Belt Conveyor System) at the Big Rock Wastewater Treatment Plant in Buchanan County, Virginia and Phillip Van Dyke, the Plant Supervisor who started it up, are planning for retirement after 30+ years of service. Back in 1985, when a postage stamp was $0.22 and Michael Jordan was the rookie of the year, JMS received an order for a Belt Conveyor to move dried sludge from the Belt Press to the loading area at this plant. A 25’ sidewall horizontal-inclined-horizontal belt conveyor was supplied for this application.

The Big Rock Sewage Plant was started-up in 1987 to serve the needs of Buchanan County in Western Virginia. After 30 years of run-time, the plant will be replacing the components of the sludge drying system. Among these is the JMS Bio-BELT conveyor. The conveyor has certainly performed well over the years, with only a few of its wear parts having been replaced. In fact, the conveyor still has its original belt, which has had some splices, but is still in place. In the words of the Plant Superintendent, “The conveyor has just done its job”.

JMS prides itself on providing equipment that stands the test of time. Retiring a 30 year old conveyor is only one example of how design and manufacturing enhancements contribute to the longevity of JMS equipment. With thousands of installations in North America, there are many examples of aging JMS equipment, such as conveyors or flocculators, running at peak performance after decades.