JMS has just completed a new upgraded version of their Eco-AIR (Low Profile Cascade Aerator) Demo Unit. The JMS Eco-AIR Low Profile Cascade Aerator is used to increase the Dissolved Oxygen content of the outfall at wastewater treatment facilities to meet federal and state regulations. A dissolved oxygen content of 6mg/liter is guaranteed.

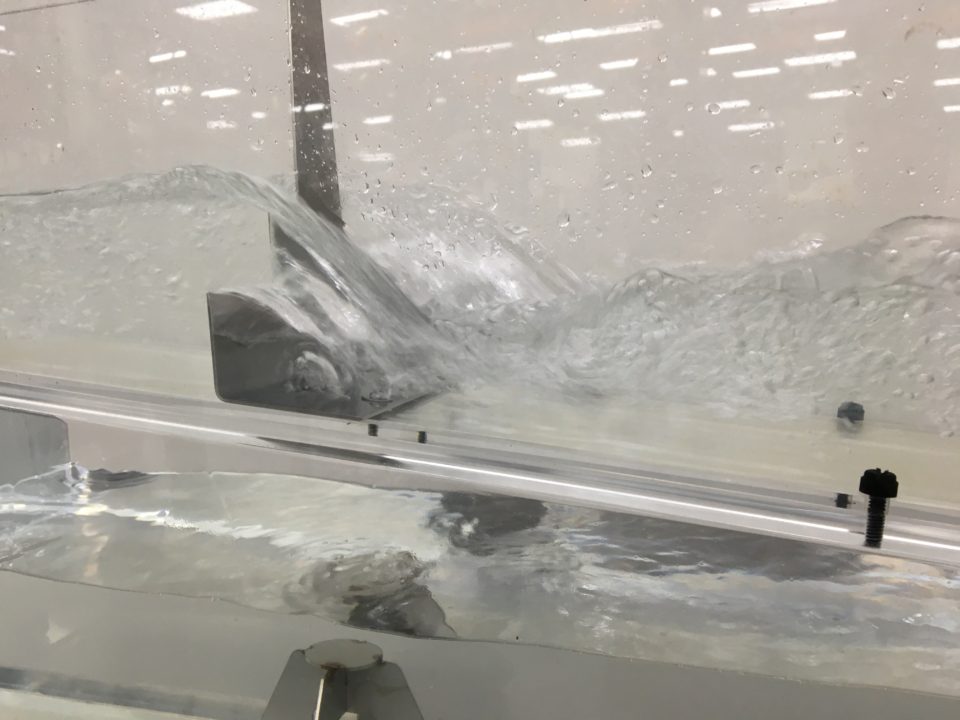

The Eco-AIR demo unit which will be used for tradeshow demonstration and in-house training, was designed to incorporate the newly patented trapezoidal air infusion plates with leaping weirs that ensure optimum performance at both low and peak flow conditions. Like a commercial unit which requires only 2.5 feet of head loss, the Eco-AIR Pilot has a slope of less than 5.5 degrees.

JMS Research and Development worked with Application Engineers to design a unit that would be both portable and withstand the demands of travel. Initially, the Eco-AIR Demo Unit will travel with a JMS Representative. For travel, the new unit breaks-down into two pieces with quick disconnect pipe connections. The flow tank uses a special thick wall acrylic guaranteed for durability.

The Eco-AIR Demo Unit will make its debut at the Kentucky/Tennessee Water Professionals Conference, July 9-12, 2017 in Lexington, KY. A JMS Representative will be there to show-off the new unit, and describe how its features can provide benefits for wastewater treatment facilities. See JMS in the Henry P Thompson booth area 154-158.