Located about 15 miles south of Milwaukee, the Oak Creek Water & Sewer Utility (OCWS) provides water and sewerage service to 70,000 people over an 83 square mile area in Milwaukee County. To meet overall growth demands of the area, the capacity of the Oak Creek WTP has grown from its original six million gallons/day (MGD) to a current capacity of more than 34 MGD. The latest expansion which made that possible also presented a number of challenges—challenges that were met through the use of newer, more efficient technology in many areas including sedimentation.

Settling on Success

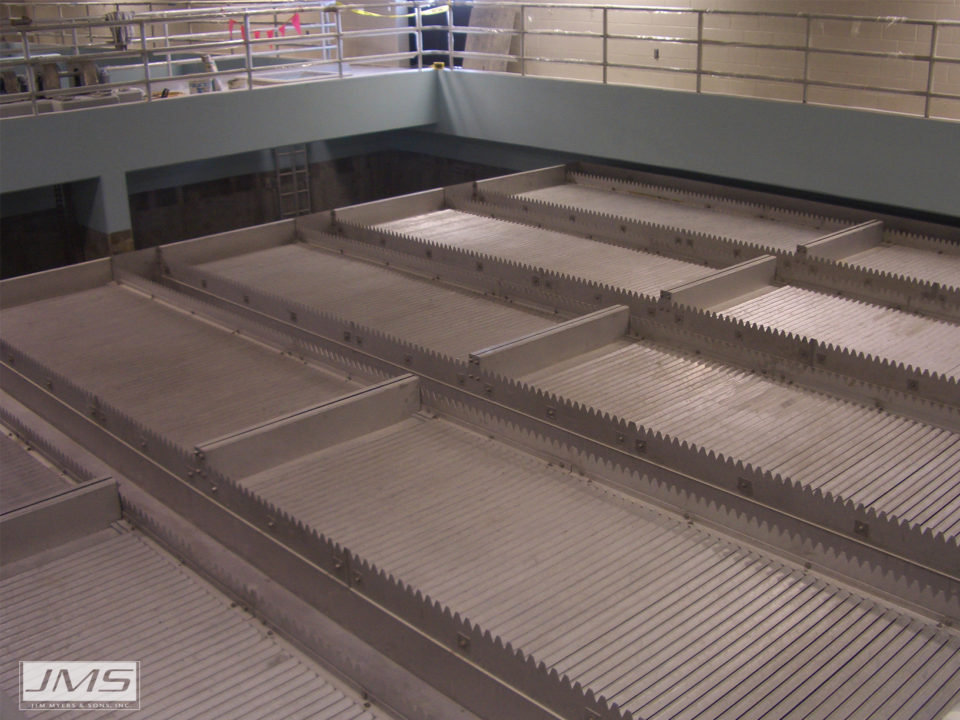

The sedimentation area is a critical step in the water treatment process and at Oak Creek, engineers hoped to not only improve water quality but also maximize the space available for expansion. They did so by specifying the use of JMS Mega-SETTLER (Plate Settler System), installed downstream from newly-installed Mega-FLOC (Horizontal Paddle Wheel Flocculator), also from JMS. Doing so greatly reduced both the size of the sedimentation basins and the building needed to house them.

The new basins were designed for a flow of 16 MGD (8 MGD each) at a plate settler loading rate of 0.33 gpm/ft2 with an efficiency factor of 100%. Knowledge of the raw water characteristics at the Oak Creek Water Treatment Plant allowed CH2M Hill’s engineer to design at this rate while exceeding effluent turbidity expectations.

Situation:

The Oak Creek Water Treatment Plant, an award-winning facility near Milwaukee, was undergoing the latest in a seriesof expansions designed to increase treatment capacities to match regional growth.

Solution:

Working through engineering giant CH2M Hill and JMS, the Oak Creek Water and Sewer Utility selected JMS Mega-SETTLER and Mega-FLOC (Horizontal Paddle Wheel Flocculator) to best meet their sedimentation related needs.

Results:

Today, the plant’s capacities are up to 34 MGD and the sedimentation area is producing a cleaner product on a significantly smaller footprint.