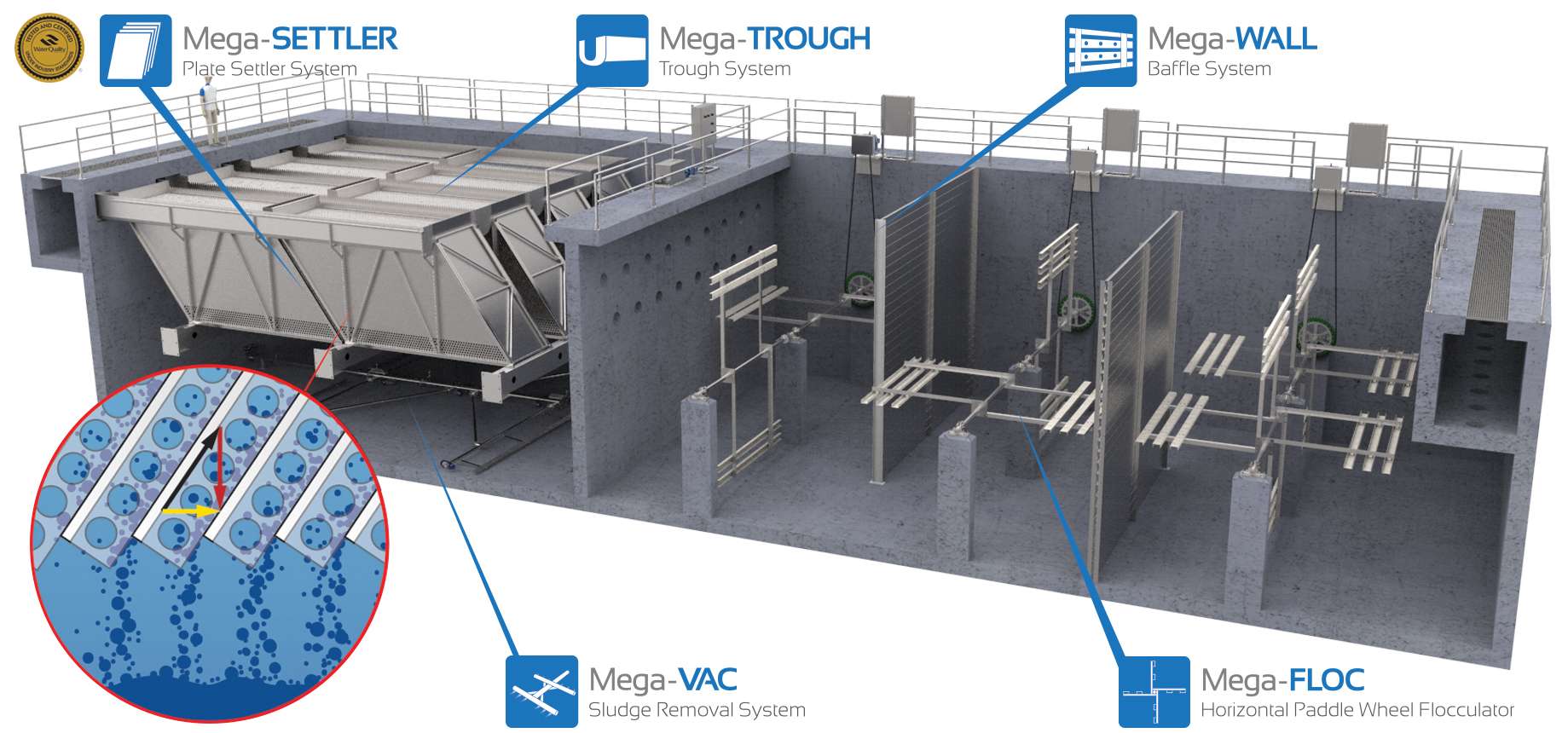

High Rate Clarification

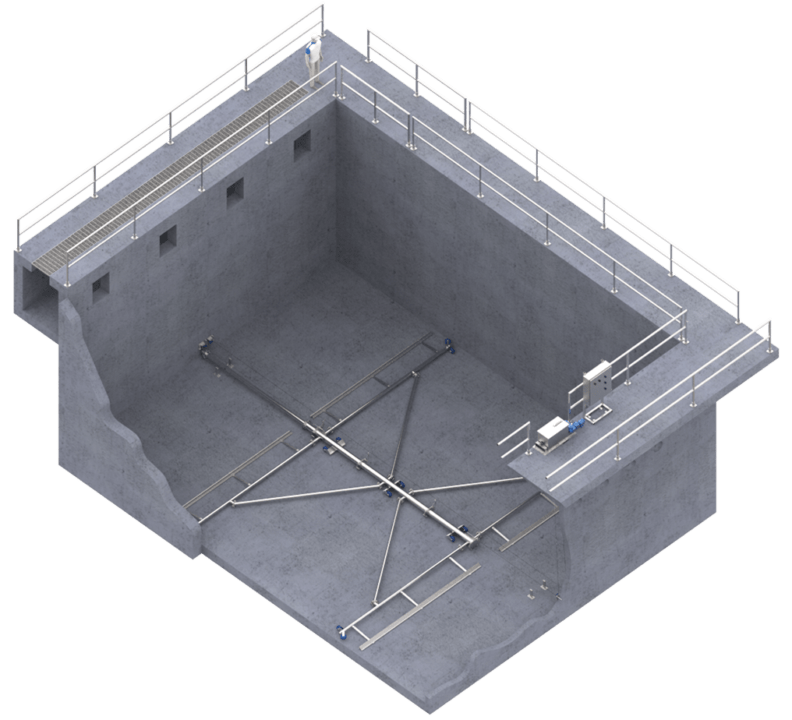

Drinking Water

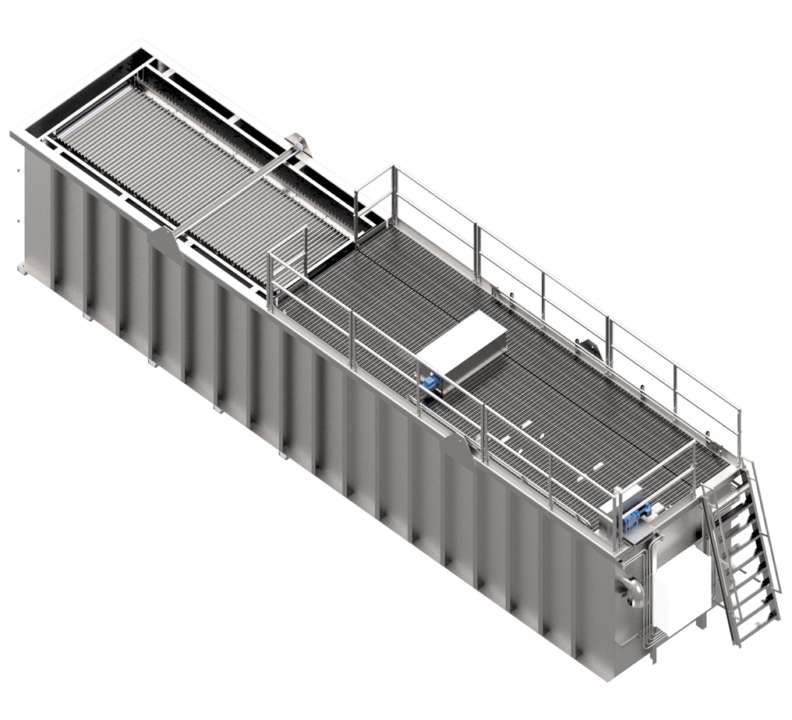

The Mega-SETTLER (Plate Settler System) for Drinking Water design program calculates the effective projected horizontal surface area required for a given design flow, while optimizing other variables critical to the process. The result is the most efficient approach possible to maximizing the treatment capacity of the basin and improving effluent quality.

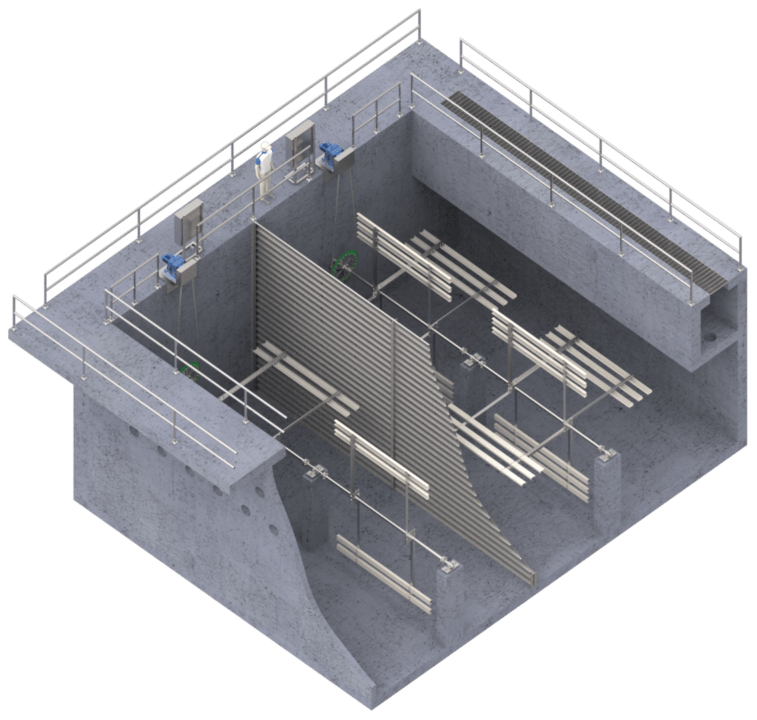

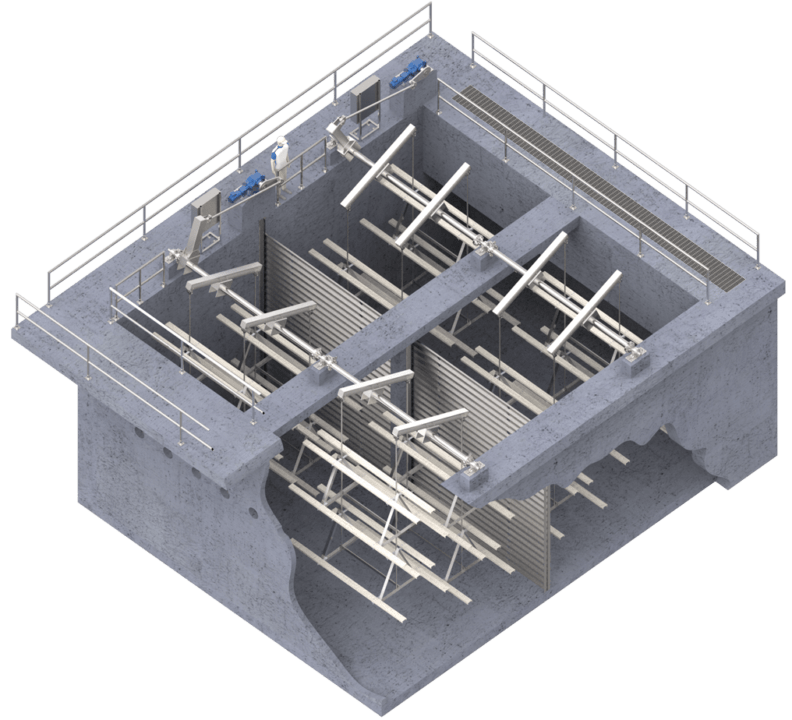

Wastewater

Plate settlers, often called inclined plate settlers, are a favored solution for upgrading a wastewater treatment plant when a new plant is not an option. The Mega-SETTLER (Plate Settler System) for Wastewater processes billions of gallons of water every day. Tested and certified to ANSI/NSF-61 standards and constructed of 100% stainless steel for superior longevity, it’s the strongest plate settler system available and the only one that can safely support the weight of operators for wash-down and service.

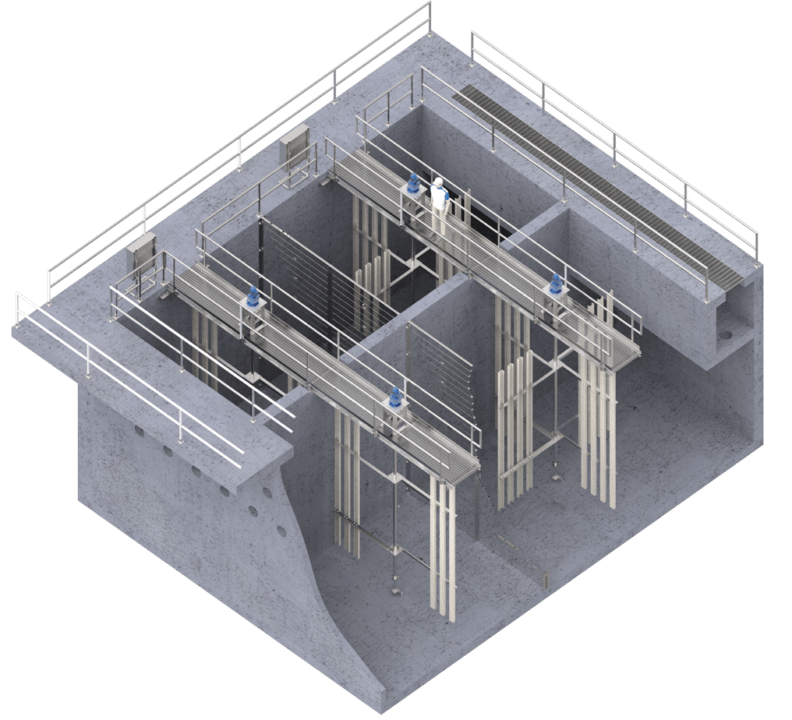

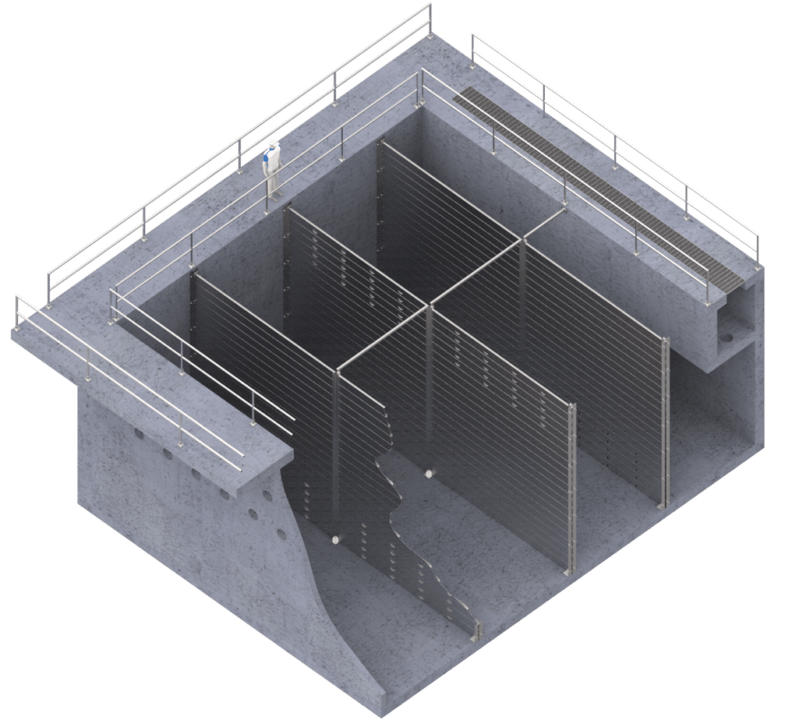

Flocculation

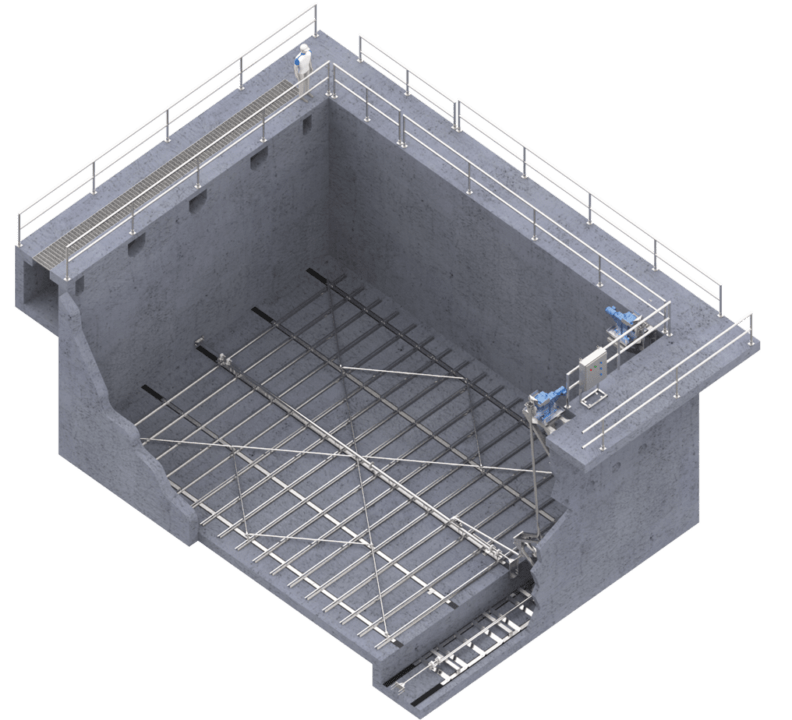

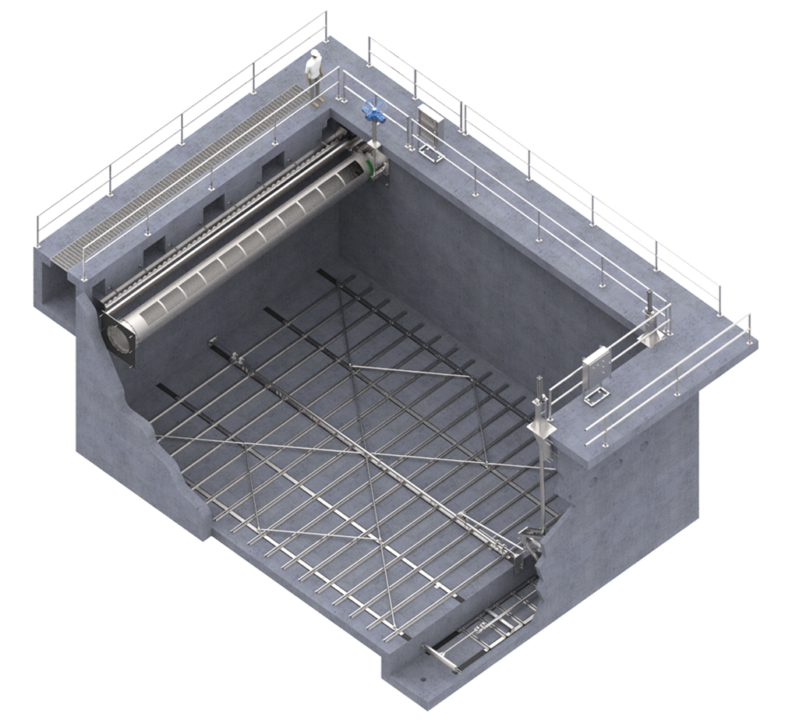

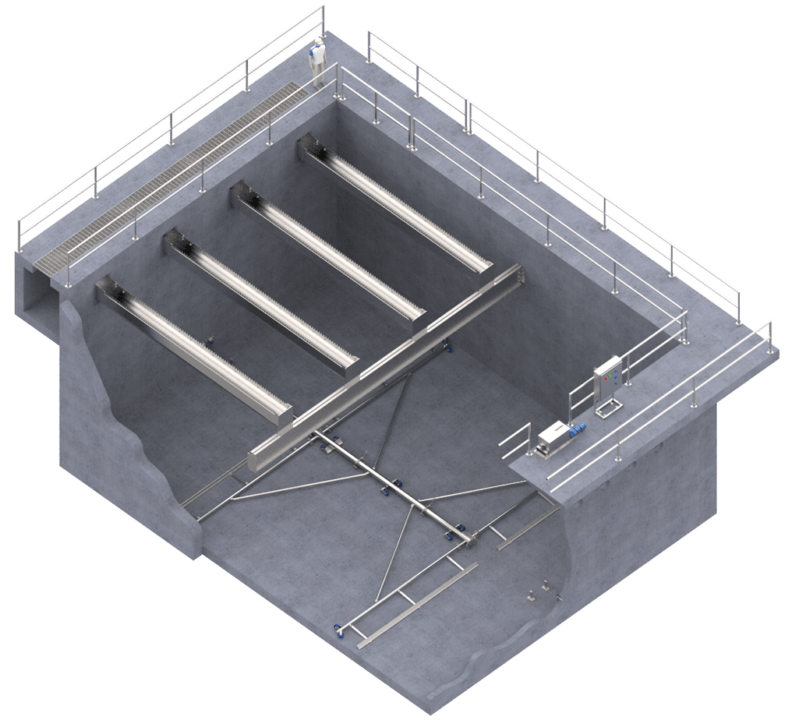

Sludge Removal

Flow Control

Systems

Aftermarket

JMS has been designing and manufacturing equipment since 1962 with over 3,000 installations. We know that technical service and the availability of quality parts are critical to your operation and to extend the life of your equipment for years to come. Given that history, we have a fully dedicated management, sales, project management, design, engineering, purchasing and field services team to support providing you the quality parts and services you need. We are ready to help you keep your system working as intended, day in and day out.