Sludge Removal

The Mega-VAC uses the hydraulic head differential between the water surface and the sludge discharge elevation. Head pressure in the basin forces sludge into the dual header orifices, and on to the discharge point for collection. This hoseless design, with proximity sensors for end of travel control, has resulted in a reliable low head-loss system, powered by gravity, effective for most water and wastewater applications.

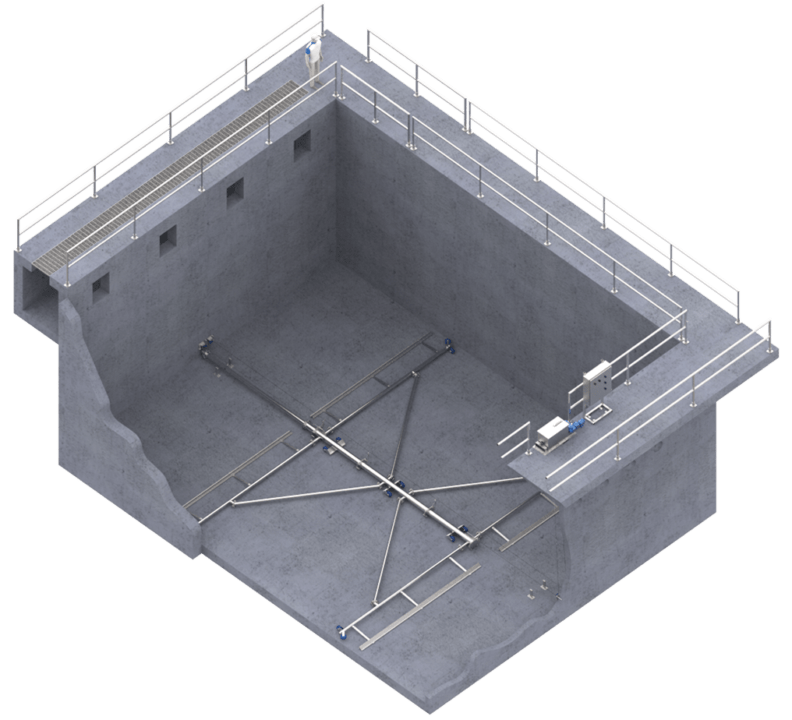

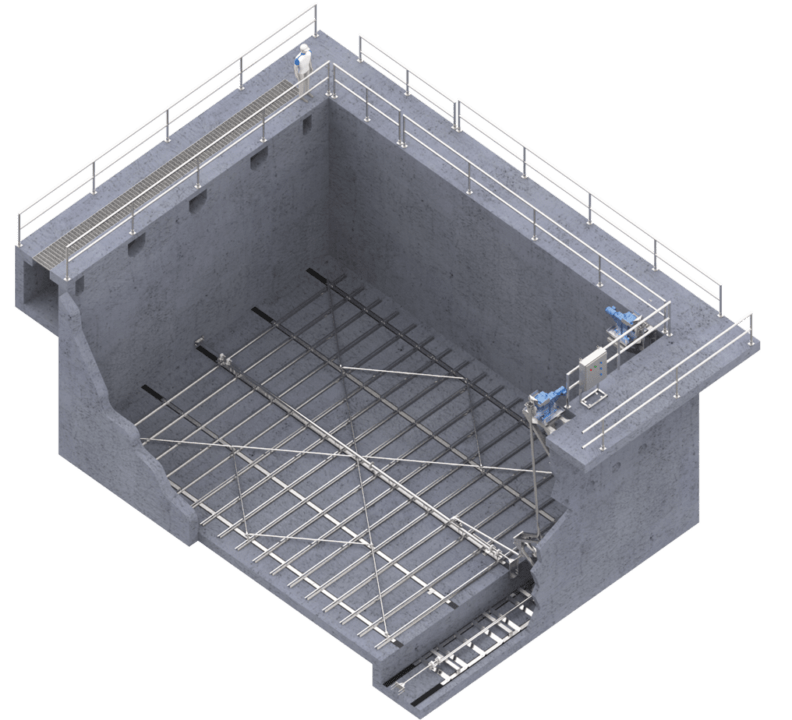

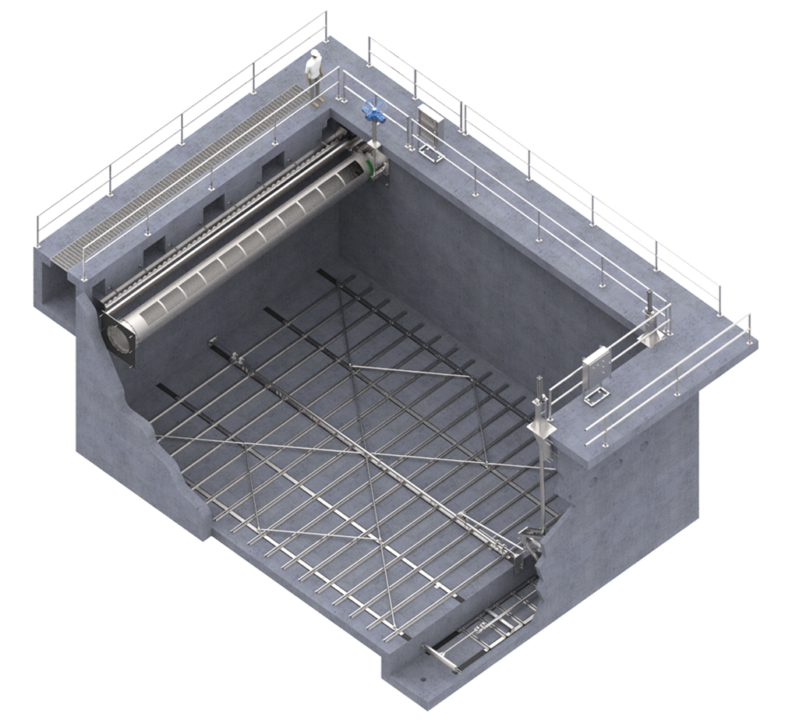

Sedimentation basins prepare water for final filtration during the water treatment process. Excessive buildup of sludge can negatively affect turbidity, tank volume and downstream membranes and filters. Based on sound principles yet flexible by design, the Mega-SCRAPER (Reciprocating Sludge Removal) has applications for water, wastewater and industrial sedimentation systems. The system is made in the USA and based on proven design concepts developed over the past 60+ years.

Scum pipes represent one of the simplest and most economical ways to remove scum from a water surface in both water and wastewater treatment. These slotted pipes rotate forward and backward by manual or electronic control, on a continuous or intermittent basis. Also called rotating scum pipes, scum skimmers, rotating pipes or rotating troughs, these systems are used in water treatment systems worldwide in circular and rectangular clarifiers, dissolved air flotation basins, settling basins and other process basins where surface scum is an issue.