A rotating scum pipe system typically extends the entire width of a basin. It is typically located at the far end of the basin, with flow towards the scum pipe, and supported at each end with an end bearing assembly anchored to the wall. The scum pipe typically has 60 degree slots along its length. In as much as the scum pipe is a weir application (i.e. ‘over-weir’), it is critical that the system be installed level. Additionally, it is critical the scum pipe is level – or near level – along its entire length. Deflection must be controlled. This is where scum pipe intermediate supports could be used.

Want to learn more about how to size a scum pipe? Read this JMS Learning Center article.

Maximum deflection tolerance should not exceed ¼” in order for the system to perform as intended. If too much deflection should occur then skimming would occur only in a confined area, and not along its full length as is desired. Additionally, once skimmed and in the pipe, the scum would need to travel up hill, if you will, to proceed to the end of the pipe.

Scum pipe variables impacting deflection:

- Both ‘buoyant’ deflection (up) and an ‘empty basin and pipe full of water’ (down) deflection must be considered

- Overall length of scum pipe (i.e. unsupported length)

- Pipe material of construction

- Pipe wall thickness

- Pipe supports (at each end)

Options for keeping a scum pipe system from exceeding maximum deflection criteria include:

- Providing an intermediate support for the scum pipe at mid-span

- Increasing the wall thickness of the pipe

- Increasing the diameter of the pipe

- Selecting a different material of construction for the pipe

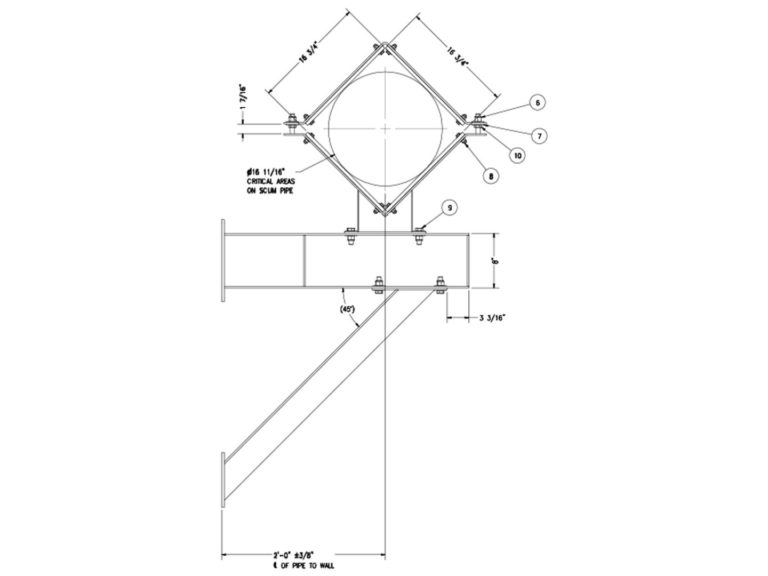

When the length of a scum pipe system drives the need to address deflection, an intermediate support is often the lowest cost and most practical solution. Other options typically involve significantly greater cost. An intermediate support consists of a wall mount bracket with an assembly that prevents vertical or lateral travel by the scum pipe when under its various load conditions. It includes a bearing surface, usually UHMW, to allow the pipe to rotate freely.

In municipal applications, where basin widths are typically 20’ or less, and where stainless steel scum pipes with ¼” wall thickness are by far most common, no intermediate support is needed.

In applications where a wall or pier is not available or practical for an intermediate support to be mounted, then other considerations are available. Selecting one of these options, or a combination of them, will offer greater rigidity and structural integrity and likely allow for deflection criteria to be met:

- Consider a different material of construction for the pipe

- Increase the wall thickness of the pipe

- Increase the diameter of the pipe

Jim Brettman has been with JMS for 9 years and serves on the sales side of the business as a Sr. Application Engineer focusing on the JMS Delta-SEPARATION. He has a BS in Civil Engineering from the University of Tennessee and worked in various positions with Exxon Co. for 12 years. After locating to Charlotte, Jim ran his own business for seven years as a rep for industrial wastewater treatment equipment and systems. Jim is proud to have worked closely with Dave Myers in closing the largest single sale by JMS to date, the Boston Deer Island Delta-SKIMMER (scum pipe) project. Jim says, “I thoroughly enjoy working with a Company that embodies integrity, quality, and service as its mantra, and working with our Reps to increase the sales of JMS products.”