Municipal Water and Waste Water Treatment plants need to use conveyance for solids, screenings, and grit. Plants choose between belt conveyors and screw conveyors. The choice between belt conveyors vs screw conveyors comes down to what materials you are conveying. Because Municipal Water and Waste Water Treatment applications have several difficult to handle products, we will cover each product separately as we assess the best conveying solutions.

Applications to consider Belt Conveyors vs Screw Conveyors

- Dewatered Sludge

- Dried Biosolids

- Raw Screenings

- Compacted Screenings

- Wet Grit

- Dewatered Grit

Dewatered Sludges:

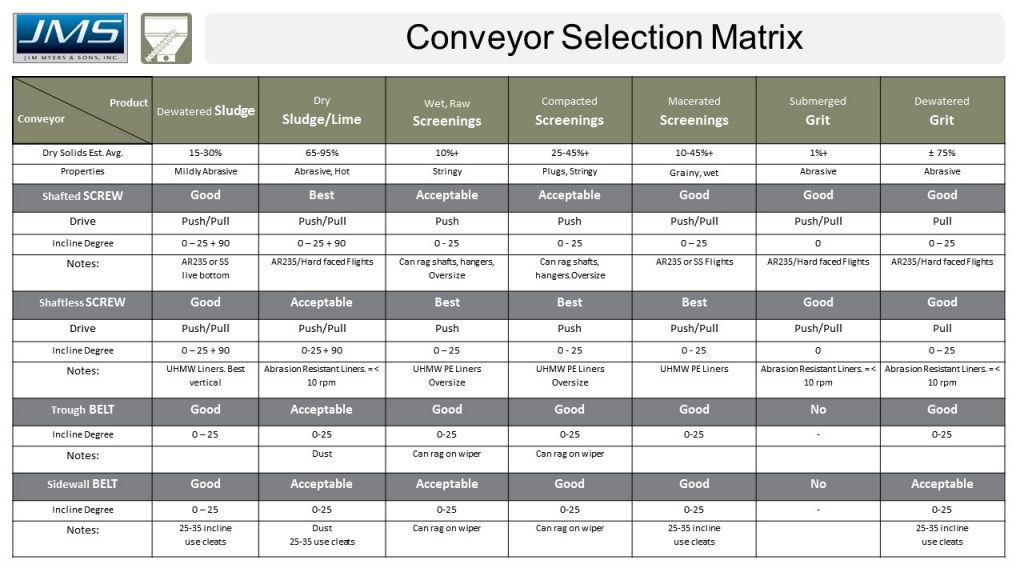

In water treatment, Alum and Ferric Chloride are used as a coagulant with a dewatering device to remove colloids and suspended solids from the water. The result is a 15%-30% dried solids (ds) sludge that has to be conveyed to a disposal container. Alum and Ferric sludges can be difficult to convey because of sticky properties. Shaftless screw & Troughing Belt are both recommended. Shafted screw and Sidewall belts are possibilities.

In waste water treatment, polymers are used for Biosolids dewatering. The result is a 15%-30%ds Biosolids sludge that has to be conveyed to a further downstream process or to a disposal container. Screw or Belt conveyors both work well with this sludge. The selection often comes down to owner preference or the layout (i.e., A. If the layout dictates a vertical conveyor, shaftless is most desirable or B. If the distance long or volume high a belt conveyor would be recommended).

Dried Biosolids:

In waste water treatment, dewatered Biosolids may be dried to almost eliminate moisture. The result is a 90%-95%ds Dry Biosolids product. Shafted screws are best as the product is too abrasive for shaftless screw liners. Belt conveyors are a possibility if the product is sufficiently cooled.

Raw Screenings:

Waste water headworks screenings deposit rags, irregularly shaped and wet product. Shaftless screws in a pushing configuration are ideal and best suited for this app as the shaftless has no tail end shaft or bearing on which for the product to “rag”. Belt conveyors are a possibility but the scraper blade can rag and has to be cleaned regularly. If there is an in-channel grinder/macerator upstream of the screen it reduces the product size and belt ragging possibilities and also opens up the possibility of using a shafted screw.

Compacted Screenings:

Waste water headworks screenings that are channeled through a compactor before conveying are dewatered to up to 45% ds. They still contain rags; irregularly shaped objects. Shaftless screws in a pushing configuration are recommended here too. Belt conveyors are a possibility but the scraper blade can rag and has to be cleaned regularly. If there is an in-channel grinder/macerator upstream of the screen OR compactor it reduces the product size and belt scraper ragging possibilities and also opens up the possibility of using a shafted screw.

Wet Grit:

Screws are often utilized in grit basins to move grit towards an underwater pump sump. Shaftless and shafted screws are both used in this application. Belts are obviously not an option.

Dewatered Grit:

Wet grit is dewatered by a classifier or grit washer. Shaftless and shafted screws are both used in this abrasive application. Belts are also utilized.

Both screw and belt conveyors have pros and cons to consider in the selection process. In general bullet points those are:

Screw Conveyors Pros and Cons

Pros

- Completely enclosed (safety, odor control)

- Less bearings than a belt conveyor

- Can convey vertically

- Used in hopper live bottom applications

Cons

- Stringy material may rag on shafts or hanger bearings

- Shearing action may change sludge

Screw Conveyors for Municipal Wastewater Plants are typically made by Jim Myers & Sons, Inc. , Spirac , Custom Conveyor Corporation , JDV

Belt Conveyors Pros and Cons

Pros

- Use less power than screw conveyors

- Does not change product as it conveys

- Best for long distances

- Best for high volumes

Cons

- Costly to enclose for odor

- Many roller bearings

- Limitations on incline degrees

Screw Conveyors for Municipal Wastewater Plants are typically made by Jim Myers & Sons, Inc. , Custom Conveyor Corporation , JDV

Greg Hyde joined the JMS Sales and Marketing Team as Product Manager | Material Handling. Greg has over 30 years of experience in material handling systems, having held high level engineering, sales and business management positions with large full line conveyor manufacturers. He is responsible for overall support and growth of the JMS Bio-HANDLING product line. Outside of work, Greg is a founding member of the “Jammin’ 4 Water” (Water Charities Fundraising Inc.). In regards to his position, Greg says, “ JMS has a rich history in design, quality and material handling. I’m excited to be part of this great team and look forward to guiding the Bio-HANDLING product family for long-term growth.”