Below is a recent presentation put together by Greg Hyde to use to present to customers about Biosolids Truck Receival Bins.

Receival Bins

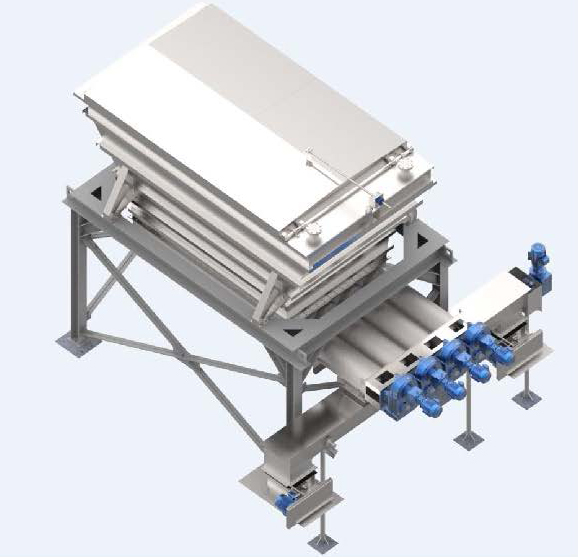

Utilized to accept foreign dewatered sludge from trucks for downstream processing. They are key equipment for quick Capex ROI for Regional processing facilities.

Designed per App

Influenced by: truck capacity & frequency; footprint & height restrictions; downstream demand or limitations.

- Capacity – Volume to meet TL requirements

- Flow/Cycle – purge time to meet frequency/demand

Typical Truck Receival Application:

- Covered truck dump area, Receival Bins in recessed pit.

- Retractable covers (personnel safety, odor control and rain protection)

- Receival Bins evacuating to downstream conveyors and/or pumps.

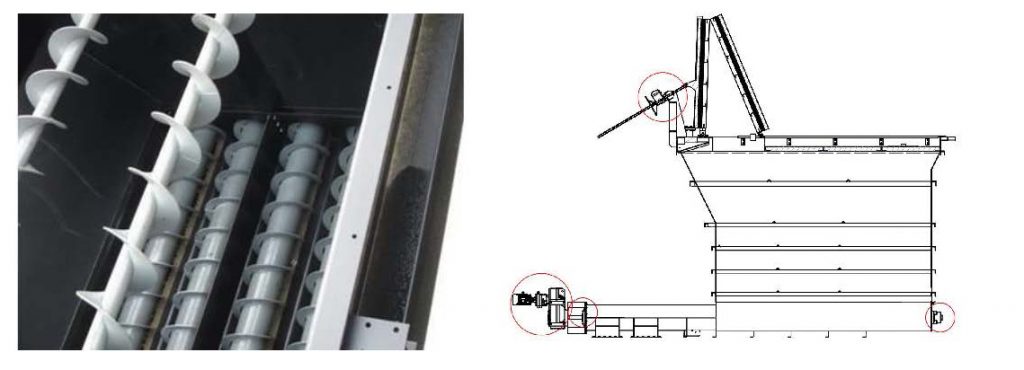

To Increase Bin Cross Section and Evacuate the Bin quickly & Completely:

- Multiple live bottom screws are utilized

- Leveling screws are used to increase usable volume

Shafted Screws and Retractable Top Require Minimal Maintenance.

- Grease Points: Screw end bearings + motor + Acme Threaded rod.

- Oil Change: Gear reducer.

- General housekeeping on retractable cover tracks.

- Easily Sourced USA replacement Parts.

VIEW GALLERY

Greg Hyde joined the JMS Sales and Marketing Team as Product Manager | Material Handling. Greg has over 30 years of experience in material handling systems, having held high level engineering, sales and business management positions with large full line conveyor manufacturers. He is responsible for overall support and growth of the JMS Bio-HANDLING product line. Outside of work, Greg is a founding member of the “Jammin’ 4 Water” (Water Charities Fundraising Inc.). In regards to his position, Greg says, “ JMS has a rich history in design, quality and material handling. I’m excited to be part of this great team and look forward to guiding the Bio-HANDLING product family for long-term growth.”