JMS has been providing scum pipes to the municipal water and wastewater industries for decades (in stainless steel T-316 or T-304, fiberglass, or carbon steel). Our Delta-SKIMMER (Scum Pipe System) uses proven proprietary JMS developments such as water lubricated bearings to eliminate the need for grease lines, and offers enhanced operation modes. The JMS system approach includes supplying all mounting hardware, anchors and epoxy, all the way to sophisticated communication with SCADA control if desired. As a leader in this industry, each day, thousands of JMS Delta-SKIMMERs are at work.

Delta-SKIMMER (Scum Pipe System) Key Features

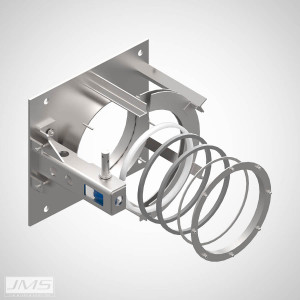

Drive Assembly

JMS Drive Assemblies allow for flexible design to handle any needs and preferences from manual hand wheel or lever control to advanced automatic controls

Worm Gear Assembly

The worm gear support assembly is adjustable to maintain proper engagement of the worm gear to the rack

End Bearing Assembly

• JMS end bearing assemblies do not require grease for lubrication

• The seals are not affected by mild acids or alkalis, and are adjustable to allow for proper sealing

Jim Brettman has been with JMS for 9 years and serves on the sales side of the business as a Sr. Application Engineer focusing on the JMS Delta-SEPARATION. He has a BS in Civil Engineering from the University of Tennessee and worked in various positions with Exxon Co. for 12 years. After locating to Charlotte, Jim ran his own business for seven years as a rep for industrial wastewater treatment equipment and systems. Jim is proud to have worked closely with Dave Myers in closing the largest single sale by JMS to date, the Boston Deer Island Delta-SKIMMER (scum pipe) project. Jim says, “I thoroughly enjoy working with a Company that embodies integrity, quality, and service as its mantra, and working with our Reps to increase the sales of JMS products.”