Watch this JMS Presentation on the JMS Mega-BEARING (High Performance Bearing System). Kerry Dissinger, Vice President of JMS, discusses the Mega-BEARING, why JMS developed it, and the need it solves in the market.

What is the JMS Mega-BEARING (High Performance Bearing System)

The JMS Mega-BEARING is a stainless steel bearing system that was developed by JMS to improve the life span of a horizontal paddle wheel flocculator. Issues that the Mega-BEARING was designed to solve include; bearing wear, shaft corrosion, scored shafts, broken shafts, and more. Each of these issues can result in plants needing to pull down basins and can become a costly repair for the plant with maintenance cost, equipment cost, and not having the plant running at its optimal performance.

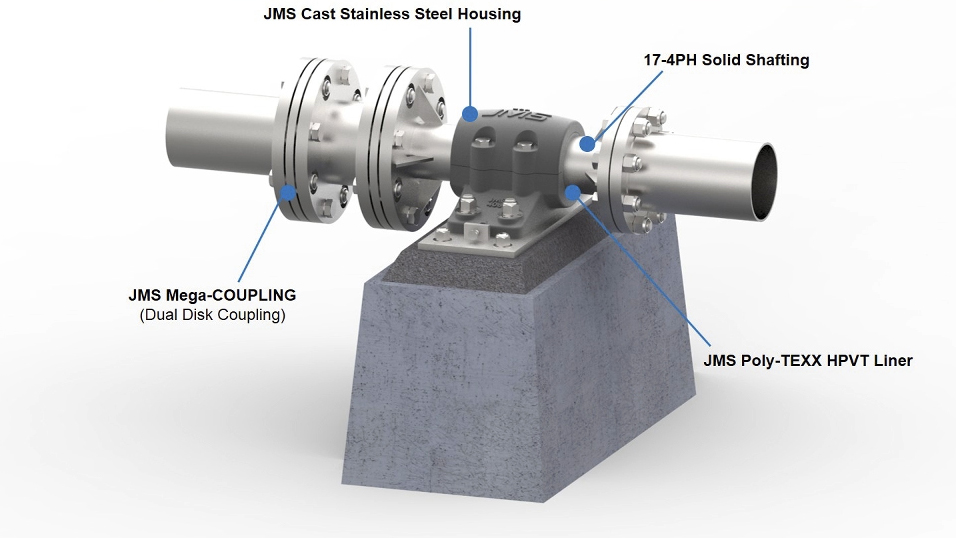

Mega-BEARING Components:

- JMS Cast Stainless Steel Housing

- 17-4PH Solid Shafting

- JMS Poly-TEXX HPVT Liner

- JMS Mega-COUPLING (Dual Disk Coupling)

Watch the rest of the JMS Mega-BEARING (High Performance Bearing System) Presentation to learn more about:

- What went into developing the Mega-BEARING

- What are each components of the Mega-BEARING

- What are the benefits of each component of the Mega-BEARING

- Success stories of the Mega-BEARING

- And more

Kerry Dissinger has been employed by JMS for the last 10 years, and currently holds the position of Vice President. Prior to receiving a BS degree in Electro Mechanical Engineering, Kerry served for 3 years as a US Army Paratrooper stationed at Fort Bragg, NC. He also served 6 years in the Pennsylvania Army National Guard. Kerry’s nearly 20 years of experience in the water and wastewater industry includes 10 years at Brentwood Industries where he was mentored by the esteemed Dr. McDowell. With his strong background in the water and wastewater process, particularly sedimentation, he is focused on continued growth and innovation, holding several active patents for JMS products. One of Kerry’s favorite sayings is: It’s not about ideas; it’s about making ideas happen.