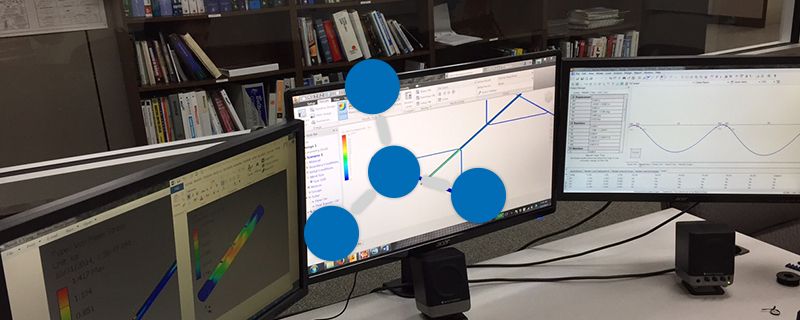

When JMS introduced the newly redesigned Mega-VAC (Hoseless Sludge Removal System) JMS did R and D on different styles of systems to choose the most optimal design. To test these designs JMS used Computational Fluid Dynamics testing (CFD Testing) to see which system performs the best. The JMS engineering team wanted to see if adding the flow balancing diagonals would help address the issue with unbalanced flow along the length of the header pipe which can lower the overall efficiency of the system.

Mega-VAC CFD Testing Set up

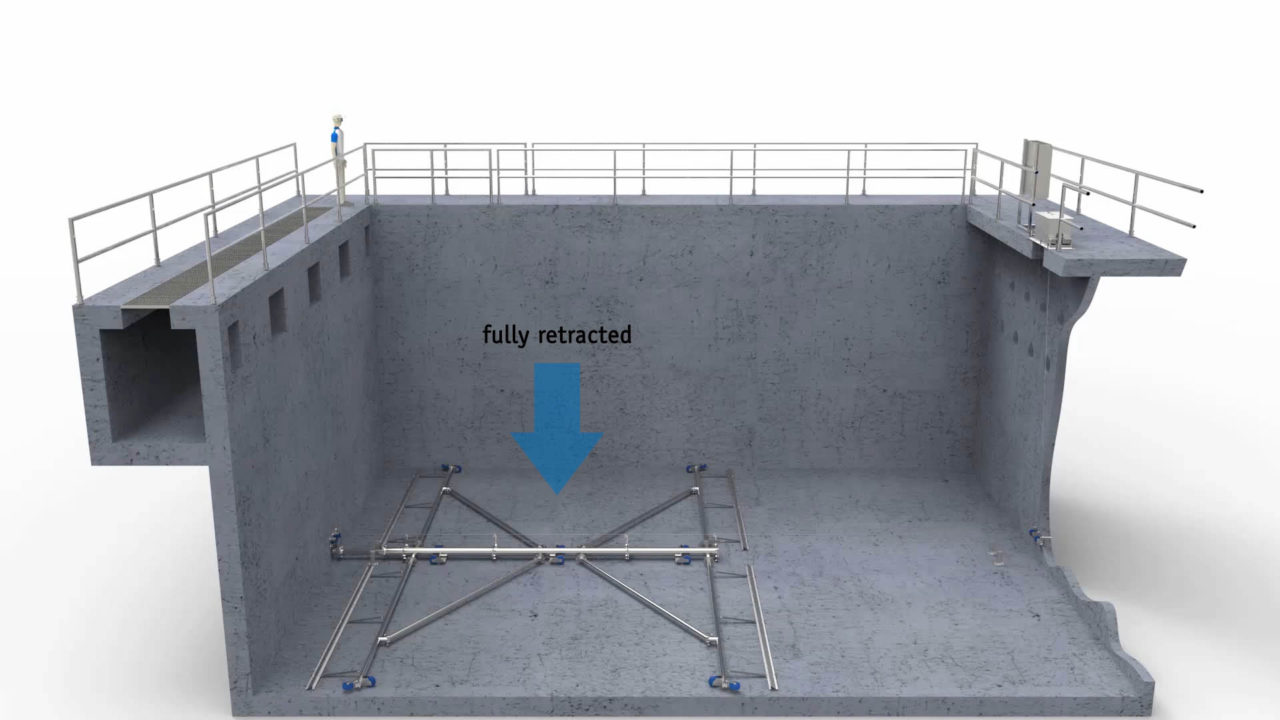

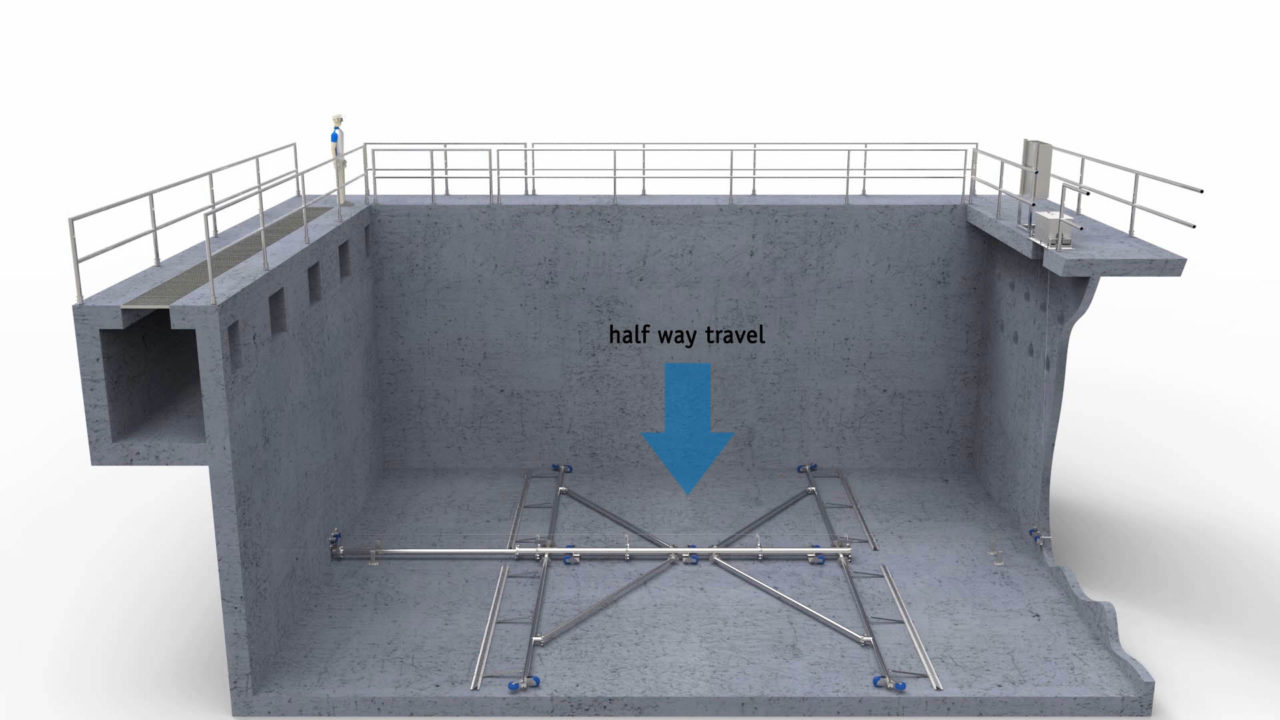

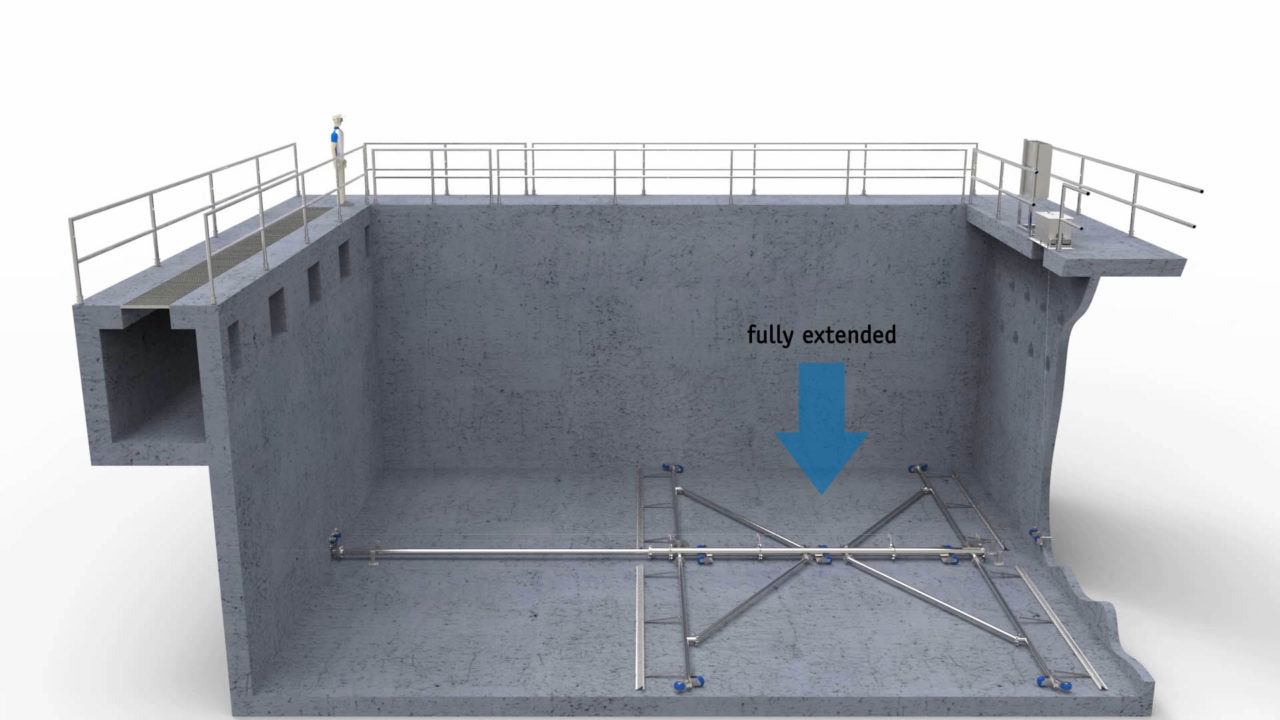

To do this test the JMS engineering team used a 30′ by 60′ model with a discharge rate of 300 gallons per minute (GPM) to simulate the size and conditions of a typical basin. The study was conducted with the header in three different positions:

- fully retracted

- halfway

- fully extended

for both designs with or without the flow balancing diagonals. Measurements were taken at each of the fifteen orifices along the length of the header.

Testing Results

For testing purposes the headers on the Mega-VAC have been labeled:

- Effluent end (closest to the discharge pipe)

- Influent end (farthest from the discharge pipe)

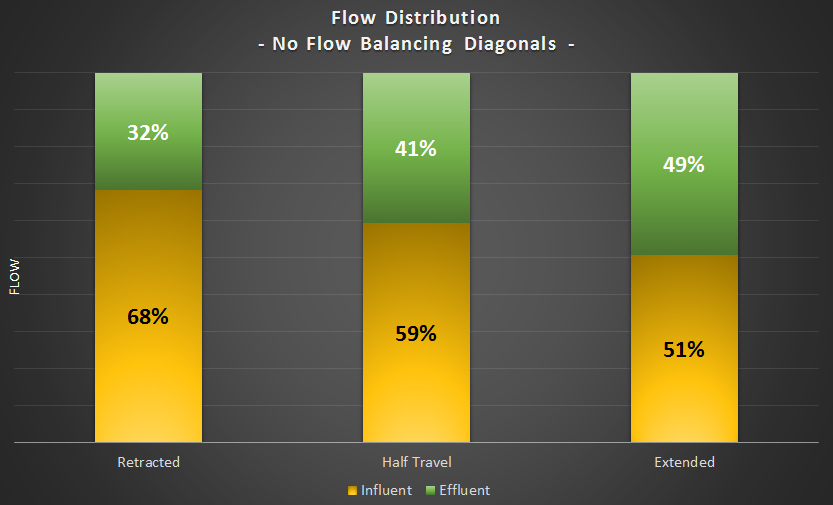

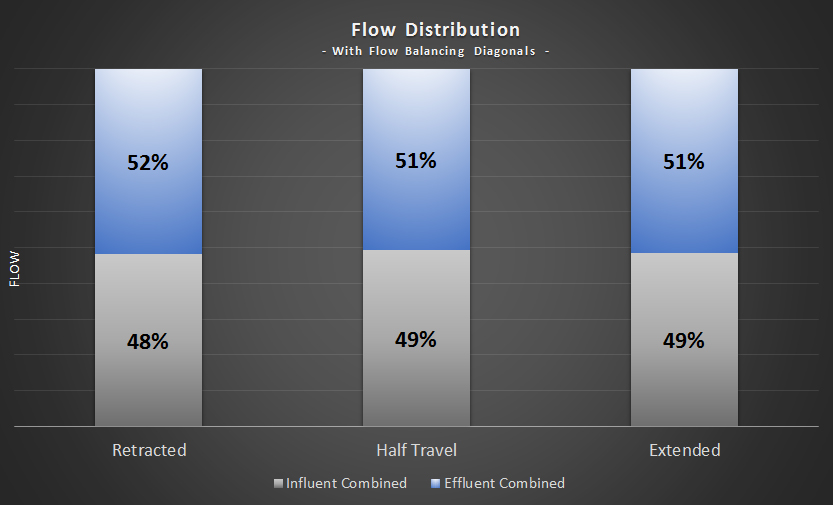

The chart on the left shows that without flow balancing diagonals an imbalance of flow across the header particularly in the retracted position. While the chart on the right shows that with flow balancing diagonals increase with flow across the header in is much more uniform at all positions.

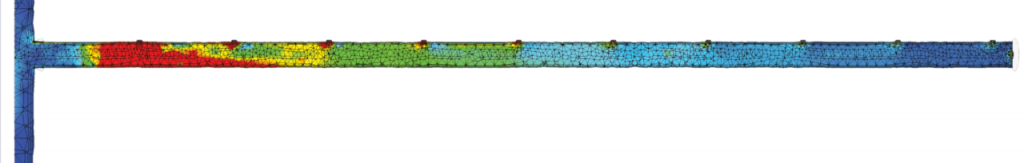

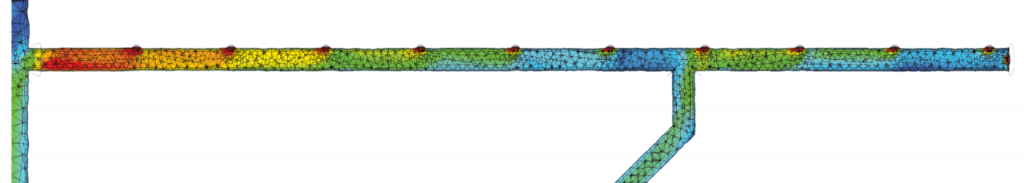

The CFD models below confirm that using the flow balancing on the Mega-VAC makes the flow across the header more significantly uniform. The top model simulates of the Mega-VAC header without flow balancing diagonals once can clearly see the spike in flow entering the influent end of the header in the retracted position. The second chart flow distribution with flow balancing diagonals, clearly shows the balance of flow across the header is much more uniform at all positions.

CFD Results of Mega-VAC Without Flow Balancing Diagonals

CFD Results of Mega-VAC With Flow Balancing Diagonals

Mega-VAC CFD Testing Conclusion

In conclusion the JMS Mega-VAC (Sludge Removal System) with flow balancing diagonals add a significant advancement in effective sludge removal from all areas of the basin. Differential pressure across the headers is minimized resulting in a balancing effect on the flow entering each orifice, no matter the header position.

Kerry Dissinger has been employed by JMS for the last 10 years, and currently holds the position of Vice President. Prior to receiving a BS degree in Electro Mechanical Engineering, Kerry served for 3 years as a US Army Paratrooper stationed at Fort Bragg, NC. He also served 6 years in the Pennsylvania Army National Guard. Kerry’s nearly 20 years of experience in the water and wastewater industry includes 10 years at Brentwood Industries where he was mentored by the esteemed Dr. McDowell. With his strong background in the water and wastewater process, particularly sedimentation, he is focused on continued growth and innovation, holding several active patents for JMS products. One of Kerry’s favorite sayings is: It’s not about ideas; it’s about making ideas happen.