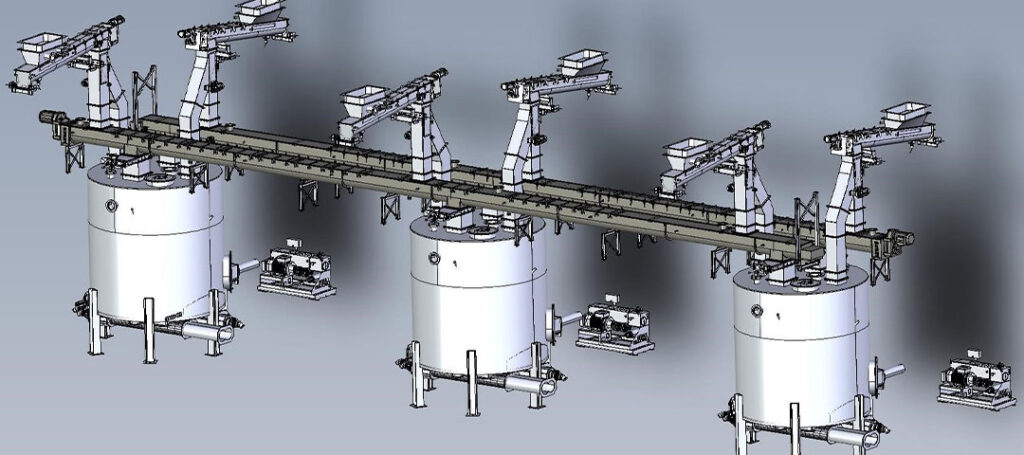

JMS’ Bio-HANDLING group is an experienced designer and manufacturer of material handling and storage equipment and complete systems. The line’s primary products are screw and belt conveyors, storage systems, silos, hoppers and receival bins with many discharger options, equipment-related structural support, instrumentation and control integration, and several supporting ancillary products such as gates, valves, diverters, plows and more. JMS is known as the premier material handling supplier in the municipal industry – water and wastewater, but the Bio-HANDLING product line also provides solutions for the Waste-to-Energy market.

What is Waste-to-Energy?

Waste-to-energy (WtE) is the process of converting non-recyclable waste into usable energy, such as electricity, heat, or fuel. WtE can be achieved through a variety of methods, including:

Incineration – The most common WtE method in the US, where waste is burned in a large incinerator to produce steam that powers an electric generator. Modern incinerators use pollution control equipment to reduce emissions.

Anaerobic digestion – An organic material or biomass is converted into biogas and compost through a biological process.

Pyrolysis & Gasification – A thermo-chemical process that converts waste into Biochar or Syngas.

Landfill gas recovery – Gases produced from decomposing biomass in landfills are captured and converted into energy.

Dendro liquid energy – A promising, near-zero emissions technology that uses moderate temperatures to generate electricity from wet or dry waste.

Hydrothermal liquefaction – A process that uses high pressure and heat to turn human waste into bio-oil, which can be refined into fuel.

Fermentation – A process that converts the sugar in waste into ethanol, similar to the process used to make wine.

Esterification – A process that produces biodiesel from waste

JMS Bio-HANDLING has been involved in incinerator, anaerobic digestion, pyrolysis and gasification material handling design in both the conveyance and storage of product, both pre and post process. Incinerators, pyrolysis and gasification are gaining intertest in the municipal market due to their ability to greatly reduce or eliminate PFAS chemicals.

Graphic source: Jim Myers & Sons, Inc. (JMS) – JMS Bio-HANDLING incinerator feed system utilizing shaftless conveyors, shafted conveyors, diverter chute gates, slide gates, sliding frame silos, piston pumps.

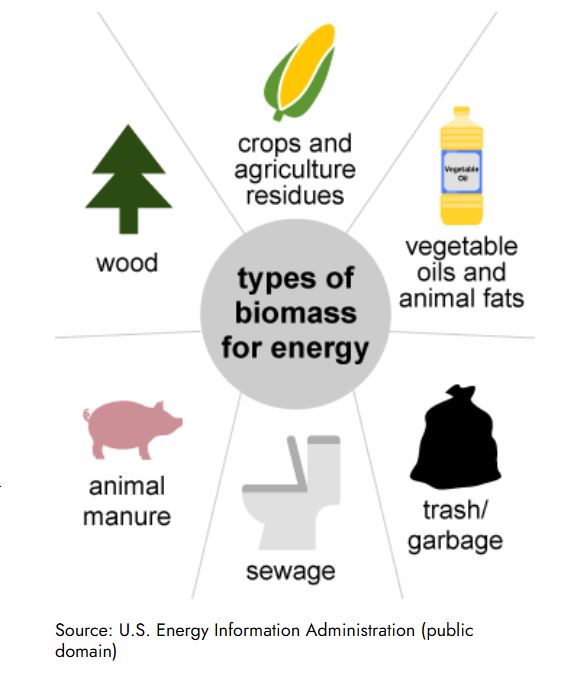

JMS has been increasingly involved in the Biomass industry beyond biosolids. What is Biomass? Biomass is renewable organic material that comes from plants and animals. This includes biosolids from municipal wastewater treatment plants. Biomass can be burned directly for heat or converted to liquid and gaseous fuels through various processes.

Biomass was the largest source of total annual U.S. energy consumption until the mid-1800s. In 2023, biomass accounted for about 5% of U.S. total primary energy consumption.

Biomass sources for energy include:

- Wood and wood processing waste—firewood, wood pellets, and wood chips, lumber and furniture mill sawdust and waste, and black liquor from pulp and paper mills

- Agricultural crops and waste materials—corn, soybeans, sugar cane, switchgrass, woody plants, algae, and crop and food processing residues, mostly to produce biofuels

- Biogenic materials in municipal solid waste—paper products; cotton and wool products; and food, yard, and wood wastes

- Animal manure and human sewage for producing biogas (renewable natural gas)

Graphic source: Jim Myers & Sons, Inc. (JMS) – JMS Bio-HANDLING incinerator feed system utilizing shaftless conveyors, shafted conveyors, diverter chute gates, slide gates, sliding frame silos, piston pumps.

Biomass is converted to energy through various processes, including:

- Direct combustion (burning) to produce heat

- Thermochemical conversion to produce solid, gaseous, and liquid fuels

- Chemical conversion to produce liquid fuels

- Biological conversion to produce liquid and gaseous fuels

Direct combustion is the most common method for converting biomass to useful energy. All biomasses can be burned directly for heating buildings and water, for providing industrial process heat, and for generating electricity in steam turbines.

Thermochemical conversion of biomass includes pyrolysis and gasification. Both processes are thermal decomposition processes where biomass feedstock materials are heated in closed, pressurized vessels called gasifiers at high temperatures. The processes mainly differ in the temperatures and in the amount of oxygen present during conversion.

- Pyrolysis involves heating organic materials to between 800° F and 900° F (400° C and 500° C) in the nearly complete absence of free oxygen. Biomass pyrolysis produces fuels such as charcoal, bio-oil, renewable diesel, methane, and hydrogen.

- Hydrotreating uses hydrogen to process bio-oil (produced by fast pyrolysis) under elevated temperatures and pressures in the presence of a catalyst to produce renewable diesel, renewable gasoline, and renewable jet fuel.

- Gasification involves heating organic materials to between 1,400° F and 1,700 F (800° C and 900° C) in a vessel and injecting controlled amounts of free oxygen or steam into the vessel to produce a carbon monoxide- and hydrogen-rich gas called synthesis gas or syngas. Syngas can be used as a fuel for diesel engines, for heating, and for generating electricity in gas turbines. When the hydrogen is separated from the syngas, the syngas and the hydrogen can be burned or used in fuel cells. The syngas can be further processed to produce liquid fuels using the Fischer–Tropsch process.

WtE and Biomass researchers are continually working on ways to improve these methods, and JMS is proud to be a contributing partner in new designs and installations.

Sources:

Greg Hyde, Jim Myers & Sons, Inc. (JMS)

US Energy Information Administration (EIA)

Google AI

Greg Hyde joined the JMS Sales and Marketing Team as Product Manager | Material Handling. Greg has over 30 years of experience in material handling systems, having held high level engineering, sales and business management positions with large full line conveyor manufacturers. He is responsible for overall support and growth of the JMS Bio-HANDLING product line. Outside of work, Greg is a founding member of the “Jammin’ 4 Water” (Water Charities Fundraising Inc.). In regards to his position, Greg says, “ JMS has a rich history in design, quality and material handling. I’m excited to be part of this great team and look forward to guiding the Bio-HANDLING product family for long-term growth.”