JMS has designed the Mega-SETTLER (Plate Settler System) to be one of the most efficient inclined plate settlers on the market. JMS did this by improving and modernizing the overall design of the plate settler that has not changed for years. Learn more about the innovation JMS has done to make the Mega-SETTLER one of the best Plate Settler Systems on the market today by watching the video or reading about the improvements below.

Mega-SETTLER (Plate Settler System) Key Features

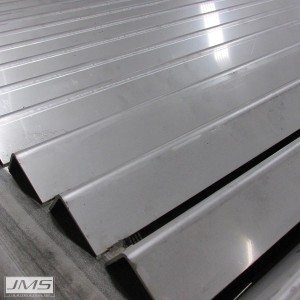

TFCA™ Top Flow Control Angle

JMS TFCA™ controls headloss and clogging issues that other designs do not address. This JMS only feature also allows for operators to walk on top of the plates for wash-down and service. JMS TFCATM also allows for the JMS Mega-SETTLER to be used in water and waste water applications.

2VNP™ Adjustable V-Notch Weirs

JMS 2VNP™ help fine tune water elevations to accommodate fluctuations in plate flow. This JMS only feature also help acquire even flow distribution across all plates.

Dual Side-Loaded Effluent Troughs

JMS Dual Side-loaded Effluent Troughs help address the issues of reduced visibility, access to the plates, and velocity accumulations resulting in imbalanced flow.

Kerry Dissinger has been employed by JMS for the last 10 years, and currently holds the position of Vice President. Prior to receiving a BS degree in Electro Mechanical Engineering, Kerry served for 3 years as a US Army Paratrooper stationed at Fort Bragg, NC. He also served 6 years in the Pennsylvania Army National Guard. Kerry’s nearly 20 years of experience in the water and wastewater industry includes 10 years at Brentwood Industries where he was mentored by the esteemed Dr. McDowell. With his strong background in the water and wastewater process, particularly sedimentation, he is focused on continued growth and innovation, holding several active patents for JMS products. One of Kerry’s favorite sayings is: It’s not about ideas; it’s about making ideas happen.