The JMS Mega-SYSTEM (Packaged Plate Settler System) is a versatile, modular water treatment solution designed to bring the advantages of high-rate plate settler technology to lower flow facilities, facilities limited on physical space, or pilot-scale applications. It was developed by JMS engineers to meet the needs of municipal or industrial water treatment applications. Using the same proven concepts as our Mega-FLOC (Flocculator Systems), Mega-SETTLER (Plate Settler Systems), and Mega VAC (Sludge Removal Systems), Mega-SYSTEM units are custom-designed for the requirements of each application.

Here’s why it stands out:

Key Benefits

1. Scalable & Compact Design

- Ideal for smaller treatment plants or modular/scalable setups—supports flows from 50 to 700+ GPM in a single, transportable unit. Multiple units can be combined to provide increased water production as needed.

- For pilot testing, JMS offers a mobile model (40–110 GPM) with 275 sq ft of settling surface—perfect for site-specific optimization and validation.

2. All-in-One, Pre-Packaged Convenience

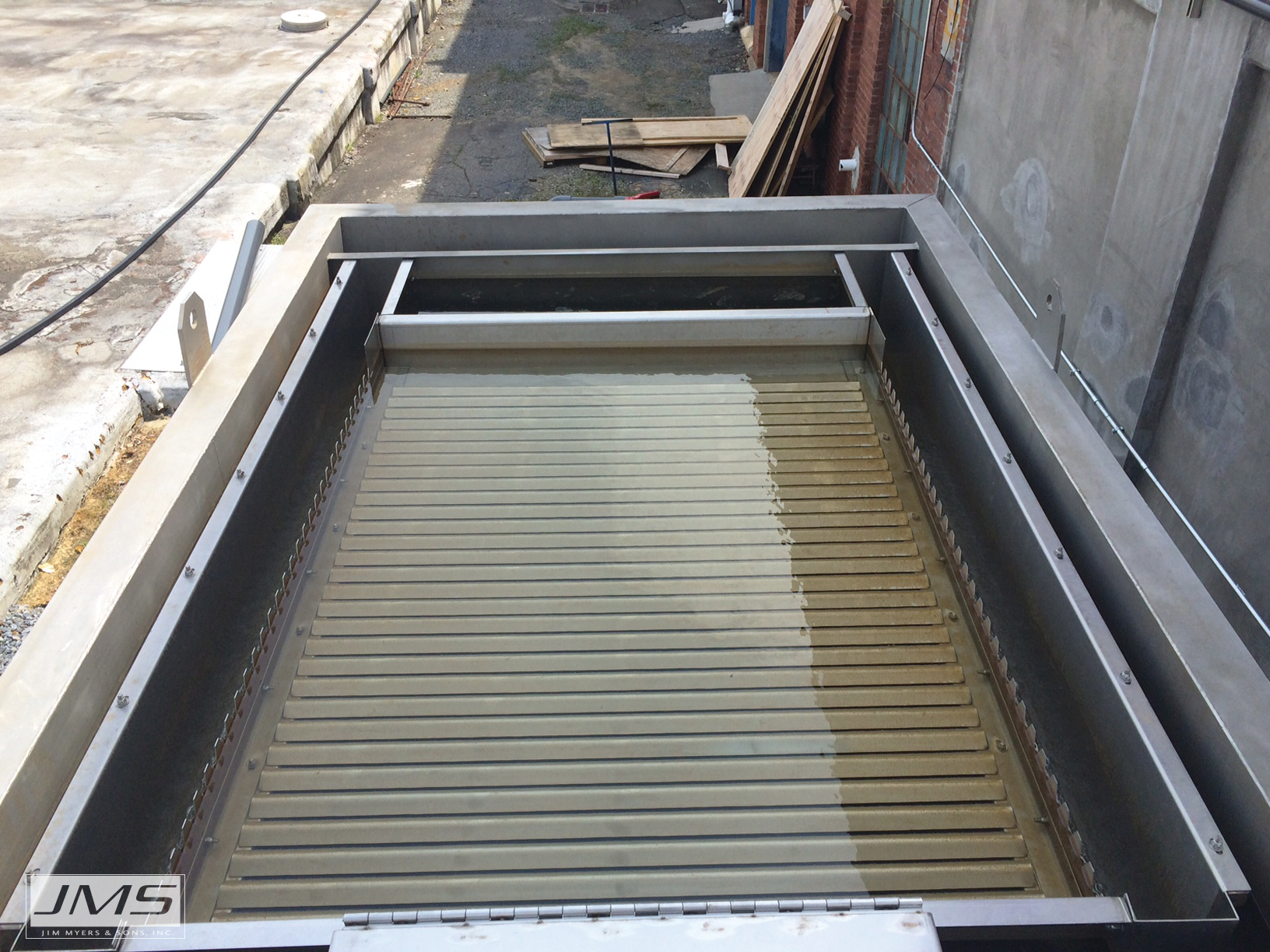

- Preassembled with integrated rapid mix, flocculation, plate sedimentation, and sludge removal systems—ready to pipe in and operate immediately.

- Stainless steel construction is corrosion-resistant and NSF61 certified, ensuring reliable water contact quality and long life expectancy.

- Package system significantly reduces installation time and cost compared to custom-built basins.

3. Performance Boost & Space Efficiency

- Uses the proven JMS Mega-SETTLER design program—ideal for footprint reduction in small or retrofit treatment plants.

- Plate settlers enhance sedimentation rates, enabling smaller footprint and higher capacity per unit area.

- Patented features address issues like head loss, clogging, and maintainability, ensuring efficient, uniform flow through plates.

4. Pilot Testing: Data-Driven Process Optimization

- Pilot units are extensively outfitted to refine:

- Plate settler loading rate

- Chemical dosing and timing

- Velocity gradient and flow mixing

- Downstream capacities of filters or membranes

- Pilot units allow engineers to tailor configurations prior to full-scale deployment, reducing risk and ensuring optimal results, as well as allowing proof of concept to governing bodies.

5. Operational & Maintenance Advantages

- Stainless steel and quality engineering reduce wear and longevity concerns.

- Integrated design simplifies operation and makes maintenance more manageable.

- Rental availability provides flexibility for short- or mid-term demand without capital investment and provides treatment capabilities during unexpected plant outages.

Why It Matters

- Faster Deployment: Off-the-shelf delivery with minimal installation delays.

- Data-Backed Design: Pilot testing ensures performance before scaleup.

- Greater Efficiency: Maximize treatment in a compact space.

- Lower Risk & Cost: Avoid extensive construction delays.

Final Thoughts

JMS Mega-SYSTEM’s modular design, combined with pilot-ready flexibility and NSF61 certified durability, makes it a powerful asset for facilities needing scalable, efficient clarification solutions without the expense or complexity of tailored infrastructure. Whether for pilot trials, smaller site or reduced flow operations, or retrofit upgrades, it tightens timelines and boosts treatment outcomes.

If you’re exploring ways to improve sedimentation in limited space or want to pilot processes ahead of expansion, the JMS Mega-SYSTEM offers a smart solution.