Rotating scum pipe system is the most popular and most common option employed for collecting floating scum at municipal treatment facilities. There are numerous customized options available in the design of a system, both in materials of construction and the way you operate a scum pipe. A scum pipe can range from a simple manual operation to a fully automated operation.

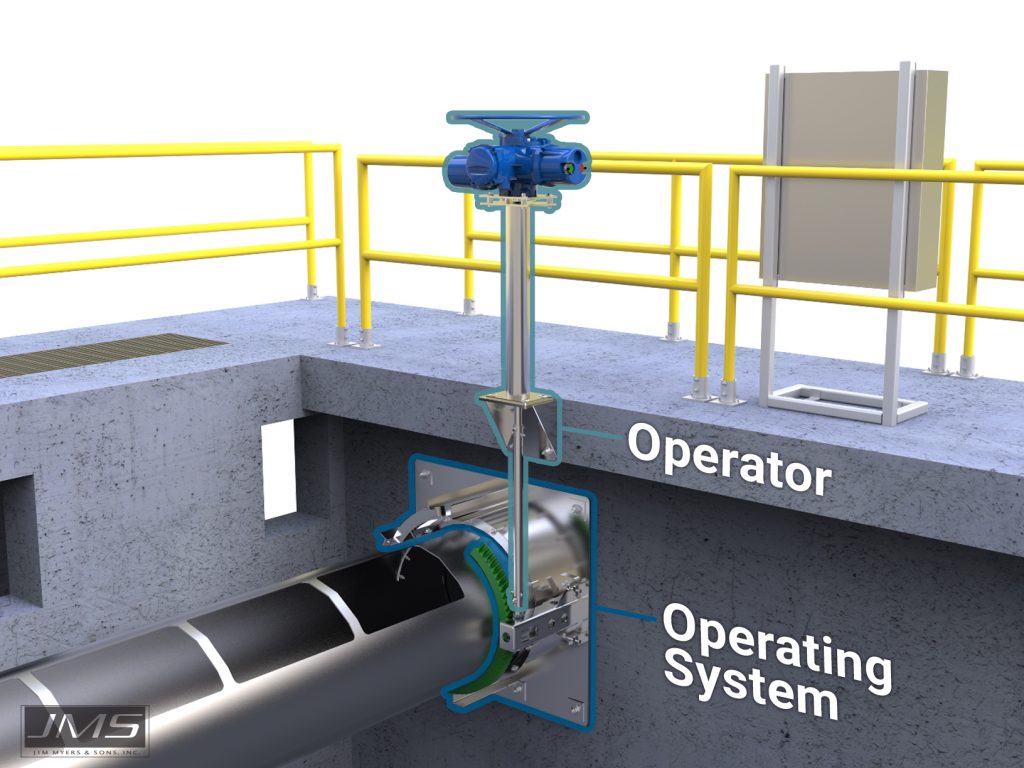

There are two parts to the method of operation for a scum pipe system – the operator, and the operating system. The operator is the component of the system that a person has to interact with to adjust the rotation of the pipe. The operating system is the mechanical assembly that interacts with the scum pipe causing it to rotate.

Reasons for Selecting a Particular Method of Operation

The reason for selecting a particular method of operation is driven by a number of considerations. First one must understand that scum pipe systems are operated intermittently to collect floating scum. A key factor in selecting the method of operation is the rate of accumulation of scum on the surface of the water in the basin. Another factor is to consider how many scum pipes you have – just one? Or do you have multiple scum pipe systems connected to each other ‘in a row’, and whether will they be operating simultaneously. Another consideration is to consider the manpower and frequency of operation. The quantity of scum pipe systems and frequency of the need for each of them to be rotated can significantly influence the decision, whether to employ a manual or automated method of operation.

Types of Operator for a Rotating Scum Pipe

A Lever operator for a Scum Pipe is the simplest of all the operator systems available. This is simply a manually operated Lever that functions as the operating system. It is the least expensive option available, but is also the most limiting, as it can only operate one scum pipe system at a time, and cannot be used with a SCADA System.

A Lever operator for a Scum Pipe would be good for a plant that:

- Has a relatively slow rate of scum accumulation

- Has a smaller quantity of scum pipe systems to operate

- Has plant personnel to continuously monitor and adjust each system

A Hand Wheel operator is another manual option for consideration. This is an easier manual method to employ than a Lever, requiring less physical effort. A Hand Wheel always employs a Worm Gear and rack operating system. It is a bit more expensive than the Lever method, but is still a cost effective option, and the most common manual operation selected. It has the same limitation as a Lever system in that it can’t be used with a SCADA system.

A Hand Wheel operator for a Scum Pipe would be good for a plant that:

- Has a moderate rate of scum accumulation

- Has a smaller quantity of scum pipe systems to operate

- Has plant personnel to continuously monitor and adjust each system

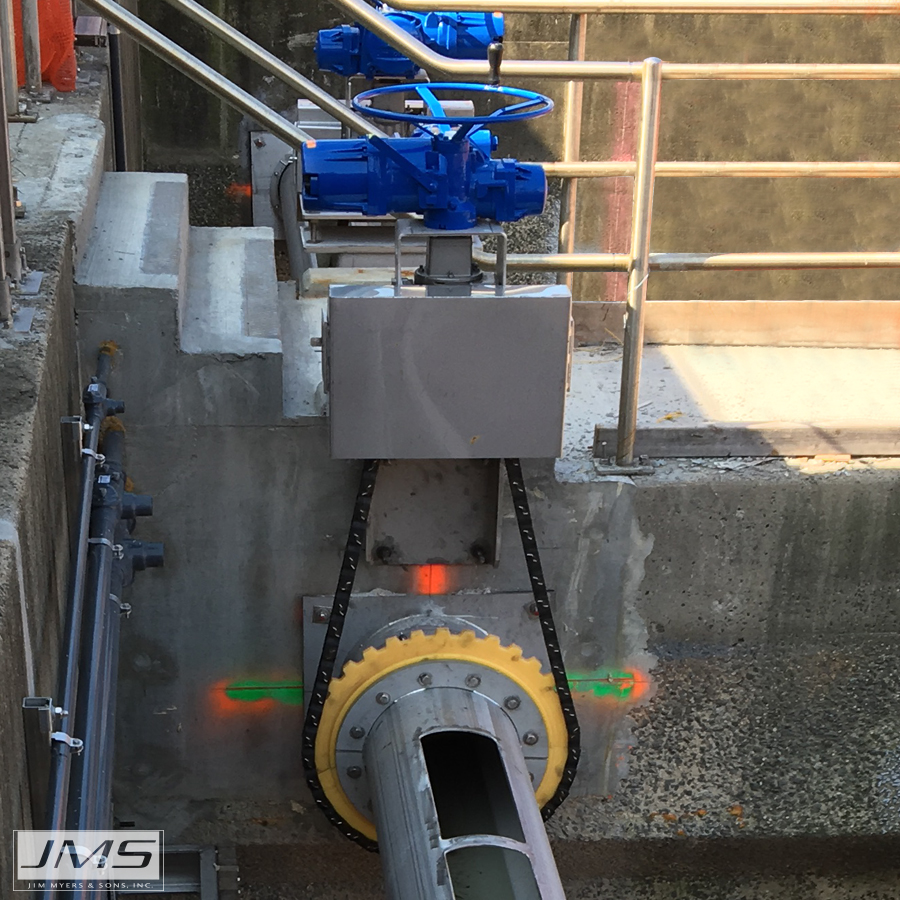

An Electric Actuator is a fully automated operator. This method is used with either a Worm Gear and rack operating system, or a chain and sprocket operating system. This is the most costly system of all options, but allows for full SCADA automation of all scum pipe systems eliminating manpower requirements and human error.

An Electric Actuator operator for a Scum Pipe would be good for a plant that:

- Has a higher rate of scum accumulation

- Has a greater quantity of scum pipe systems to operate

- Wishes to reduce manpower costs for the monitoring and adjusting each system

Types of Operating Systems for a Rotating Scum Pipes

Again, Lever operated systems are a manual operation.

A Worm Gear (with gear rack) is one of the most popular styles of operating systems used for scum pipes at municipal plants. This style of operating system can be used with either a manual Hand Wheel operator, or an automated Electric Actuator operator. Worm Gear is more expensive than a Lever operating system but is still cost effective. It is a good option for a plant that has a modest amount of scum accumulation, and can be used for either a manual or automatic system.

A Worm Gear operation System for a Scum Pipe would be good for a plant that:

- Has a moderate rate of scum accumulation

- Employs smaller diameter scum pipe systems

The Chain and Sprocket is an excellent option for an operating system for larger diameter scum pipe systems. This method of operation is employed only with actuated, automated systems. It is a more costly option in initial capital cost, but is the heaviest duty, robust design offering long life with low maintenance costs. This method is excellent for plants that employ scum pipes of 12” to 24” diameter, and for applications that have a high rate of scum accumulation, and employ multiple scum pipe systems.

A Chain and Sprocket operation System for a Scum Pipe would be good for a plant that:

- Will employ actuated, automated scum pipe systems

- Has a high rate of scum accumulation

- Employs larger diameter scum pipes (12” and greater)

Jim Brettman has been with JMS for 9 years and serves on the sales side of the business as a Sr. Application Engineer focusing on the JMS Delta-SEPARATION. He has a BS in Civil Engineering from the University of Tennessee and worked in various positions with Exxon Co. for 12 years. After locating to Charlotte, Jim ran his own business for seven years as a rep for industrial wastewater treatment equipment and systems. Jim is proud to have worked closely with Dave Myers in closing the largest single sale by JMS to date, the Boston Deer Island Delta-SKIMMER (scum pipe) project. Jim says, “I thoroughly enjoy working with a Company that embodies integrity, quality, and service as its mantra, and working with our Reps to increase the sales of JMS products.”