Flocculation is an important part of the Water Treatment process. “Flocculate is a verb meaning to form flocculant masses, as a cloud or a chemical precipitate; form aggregated or compound masses of particles.”

Why would I want to flocculate? The 1000’ view reasoning in the municipal water industry is to begin the process of separating dirty particles from water to create clean drinking water. Large size particles known as flocs have a higher density, and hence a higher settling rate.

Both Impeller Style, and Paddle Wheel Style Flocculators can be used in a Water Treatment settlement basin. Each type of mixer has its positive and negatives, and the engineer must weigh the needs of the process along with the positives and negatives of each type of mixer in making his/her choice for the plant design.

Impeller Style Flocculators

Think of a boat or airplane propeller. The Impeller Style generally takes up less space in a basin and turns at a much higher frequency compared to other style flocculation systems. For Water Treatment systems, turbines with a strong axial component are generally chosen. These types of mixers are manufactured by Philadelphia Mixer, and Lightnin Mixer, among others.

The goal of the Impeller Style mixer is to create an economical, high torque, and low horsepower unit. This can translate into lower energy input and reduced operating expense. There are, however other considerations to weigh when looking at the full cost of this system over its lifetime.

While the Impeller Style mixer may have a lower initial cost, additional costs for mounting bridges, power distribution to each mixer, including SCADA control, and emergency shut-offs need to be included in the total cost equation for this type of mixer.

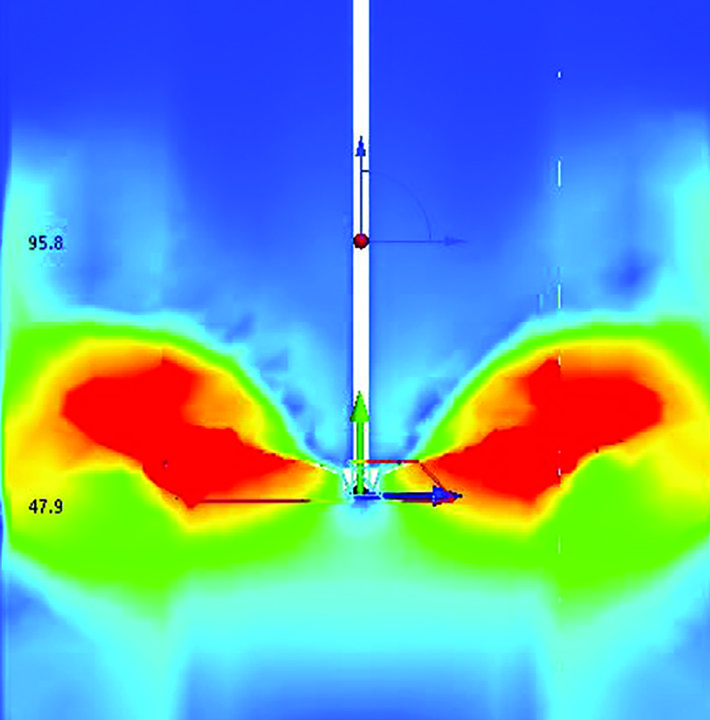

Impeller Style mixers are designed to produce adequate mixing with the lowest turbulence possible. Inherent in their design, however, may be a tendency to have dead spots, contrasting with other areas with a high velocity gradient (turbulence). Mass rotation also occurs. Impeller mixers produce a very high tip speed that tends to bread-down the floc. Once broken-down, floc masses will not reform.

The Impeller Style mixer has one gear box for each impeller which will need routine servicing and a power distribution system. Each gear box must support the entire weight and torque output of the unit without an external thrust bearing. Assessing the expected lifetime of the mixer may be wise.

Paddle Wheel Style Flocculators

Paddle Wheel Flocculators could be compared to the slow moving paddle wheel of a paddle wheel boat. Paddle Wheel Flocculators are available in Horizontal, Vertical , and Walking Beam Paddle Wheel designs. This type of flocculator mixer is manufactured by Jim Myers & Sons, Inc. (JMS), as well as Amwell, JDV, WesTech, and EIMCO among others. As is the case with Impeller Style mixers, the Paddle Wheel Flocculator comes with its own set of positives and negatives.

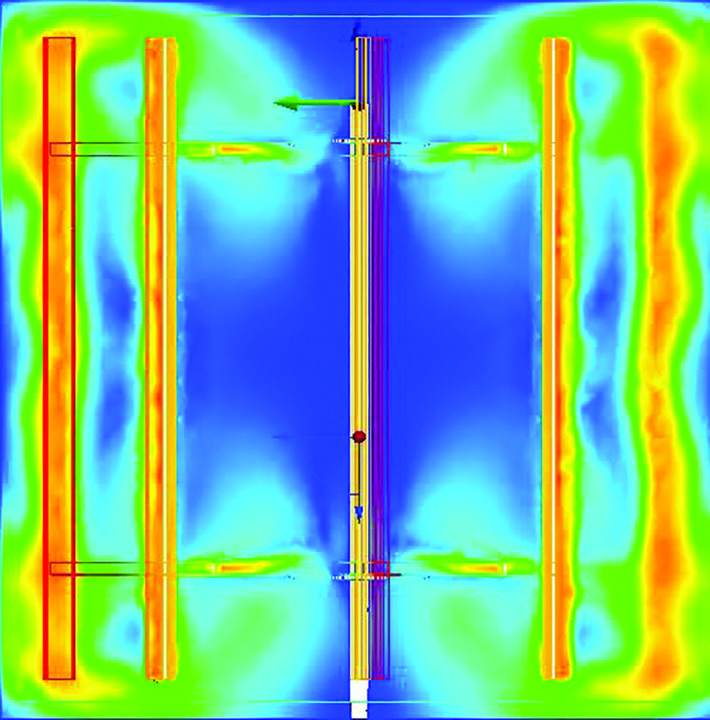

Paddle Wheel Flocculators have traditionally been used in the municipal Water Treating process, primarily because their slow speed, low shear mixing method is well suited to the flocculation process in a Water Treatment basin. Multiple paddles of considerable size are used to gently mix the basin influent allowing for a robust high density floc with a high settling capacity, resulting in low turbidity effluent. The large engineered paddles reach the entire basin eliminating dead spots and short circuiting.

Both Vertical and Horizontal Paddle Wheel Flocculators are purchased as a complete unit ready for mounting, and include process control if specified. Individual Vertical Paddle Wheel Flocculators each have their own drive assembly including gear motor drive stand weldment, chain coupling, thrust collar, radial thrust bearing and drive assembly mounted to a bridge for easy installation. In the case of the Vertical Paddle Wheel Flocculator, the radial thrust bearing takes the axial, vertical and radial thrust loads to provide for a long life.

Horizontal Paddle Wheel Flocculators are also provided as a full system to meet specifications. Horizontal Paddle Wheel Flocculators are generally known as the most cost effective flocculator for large systems. This design allows for several reels to be powered by a single drive, a significant cost saving measure. Jim Myers & Sons, Inc. (JMS) has pioneered many of the upgrades that are used in this type of flocculator, including use of stainless steel for key components, proprietary leveling devices, and the new Mega-BEARING with upgraded housing and shaft materials of construction, self-aligning coupling, and specialty bearing liner. Use of the new style bearing can add to the already long life, and low maintenance for this style of flocculator.

Paddle Wheel Flocculators vs. Impeller Style Flocculators Conclusion

Choice of the right mixing device for municipal Water Treatment plant flocculation requires consideration of several variables. Paddle Wheel Flocculators require a greater upfront commitment of capital, however may be the more economical choice when all of the additional costs for mounting and control equipment for Impeller Mixers are included. Paddle Wheel Flocculators have stood the test of time as a result of the optimal mixing they provide, and have provided service to plants for decades. Through design and manufacturing upgrades that have taken place over the years, Paddle Wheel Flocculators have held their position as the choice for most new Water Treatment plants, or upgrades of older facilities.

Kerry Dissinger has been employed by JMS for the last 10 years, and currently holds the position of Vice President. Prior to receiving a BS degree in Electro Mechanical Engineering, Kerry served for 3 years as a US Army Paratrooper stationed at Fort Bragg, NC. He also served 6 years in the Pennsylvania Army National Guard. Kerry’s nearly 20 years of experience in the water and wastewater industry includes 10 years at Brentwood Industries where he was mentored by the esteemed Dr. McDowell. With his strong background in the water and wastewater process, particularly sedimentation, he is focused on continued growth and innovation, holding several active patents for JMS products. One of Kerry’s favorite sayings is: It’s not about ideas; it’s about making ideas happen.