A pilot unit is designed to replicate an entire flocculation and sedimentation basin. This unit is a portable complete system that can be delivered to a plant site. A pilot unit is used for multiple applications in testing such as potential pieces of equipment, process, downstream equipment testing, and more. Watch this recent JMS presentation, by Kerry Dissinger, Vice President of JMS to learn more about pilot testing for water treatment plants.

Types of Equipment Included in a Pilot Test Unit

Key Variables for Pilot Testing

- Plate settler loading rate

- Chemical addition

- Velocity gradient

- Filters that follow

- Membranes that follow

Plate settler loading rate is tested to find the optimal loading rate for the specific plant. This will help with deciding the number of plates needed to go into the full-scale basin. Engineers that use a pilot unit are always looking at chemical addition. An engineer will be testing different chemicals, amounts, and timing to find the best performance with the velocity gradient to see how it affects the overall performance of the plant. Typically pilot testing is not only for sedimentation or flocculation but also downstream equipment like filters or membranes.

Example of Pilot Testing in Water Treatment Plants

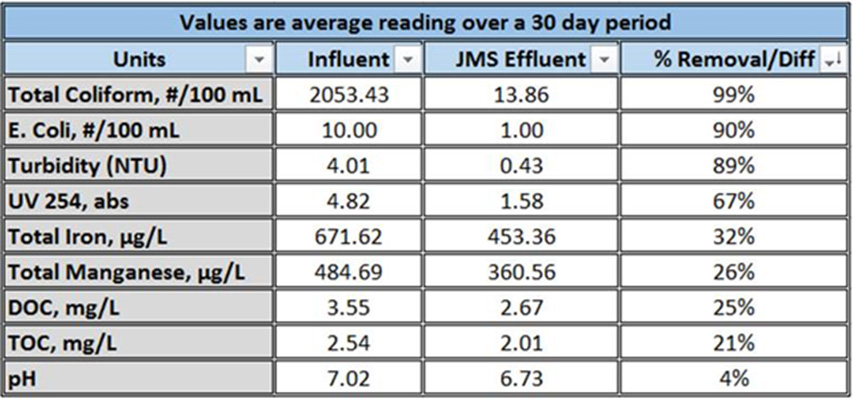

One of the main focuses on a pilot study is turbidity, this is a key factor in deciding on how a plate settler’s system is performing. A plate settler performance is based on how much turbidity (NTU) it removes. In this chart from a pilot study, the pilot unit was able to remove 89% of the turbidity. 4.01 NTU is low which means that the water source was a clean source and over a 30 day testing period the pilot unit effluent was averaging 0.43 NTU. During this testing period, there were periods where the turbidity would be spiked to 40 NTU to see how the pilot unit would perform. Even with that high of turbidity, the pilot unit was creating an effluent of 0.4 -0.5 NTU.

Watch the Rest of this Presentation to Learn More About:

- JMS pilot unit

- Installation and setup of a pilot unit

- Examples of pilot studies

- And more

Kerry Dissinger has been employed by JMS for the last 10 years, and currently holds the position of Vice President. Prior to receiving a BS degree in Electro Mechanical Engineering, Kerry served for 3 years as a US Army Paratrooper stationed at Fort Bragg, NC. He also served 6 years in the Pennsylvania Army National Guard. Kerry’s nearly 20 years of experience in the water and wastewater industry includes 10 years at Brentwood Industries where he was mentored by the esteemed Dr. McDowell. With his strong background in the water and wastewater process, particularly sedimentation, he is focused on continued growth and innovation, holding several active patents for JMS products. One of Kerry’s favorite sayings is: It’s not about ideas; it’s about making ideas happen.