Constant and/or intermittent skimming and removal of floating scum from the surface of process basins has been a necessity in municipal water and wastewater treatment processes to remove this material from the water so it can continue downstream scum free. Historically, the most common method for accomplishing this has been the rotating scum pipe system. Also called scum pipes, scum skimmers, rotating pipes or rotating troughs, these systems are employed all over the world in circular and rectangular clarifiers, dissolved air flotation basins, settling basins, and other process basins where surface scum is an issue. Scum pipes span the width of a basin, and typically have 60 degree slots cut into the pipe along its entire length, so when the pipe is rotated the surface scum falls into the pipe and travels to the end for further handling.

Scum pipes represent one of the simplest and most economical ways to remove scum and other floating materials from the water surface. These slotted pipes rotate forward and backward by various methods of manual control such as a lever or hand-wheel, or by electronic control, such as an electric actuator. They typically are rotated on an intermittent basis, but can also be left in a rotated position and operate continuously for some applications.

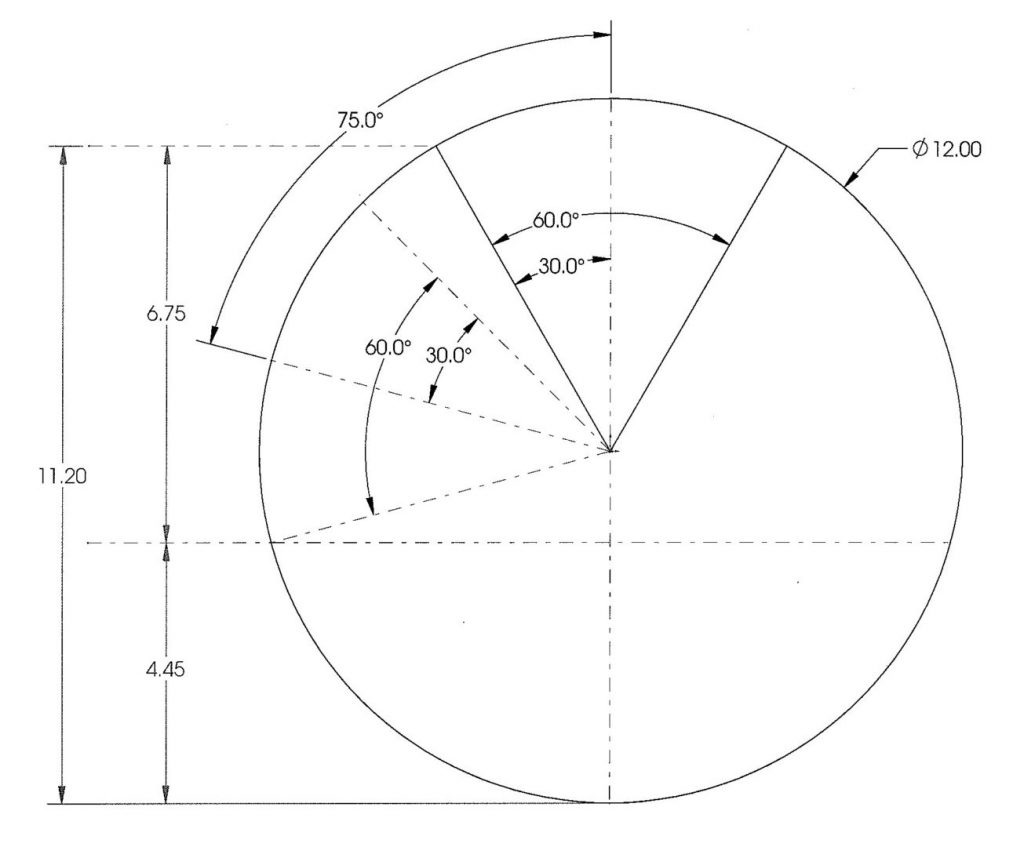

In addition to ensuring the scum pipe system is installed level, and at the proper elevation, another important thing to consider is the proper size (diameter) of the pipe for the application at hand. If a scum pipe is not sized and located properly, the range of rotation will be inadequate, or too great, for the system to perform as intended. When a scum pipe is rotated the bottom of the slots in the pipe needs to meet ‘just above’ the scum/water interface (where the scum meets the water). The mission is to skim only scum, not water. Flexibility to skim at different levels, and even beyond the interface on occasion, is desired.

What are the variables for sizing a scum pipe?

- Change in water elevation

- Location (elevation)

- Pipe diameter

- Slot design (typically 60 degree ‘cut-out’ slots with 2” stiffeners left between slots)

- Degree of rotation (typically 75 degrees in both directions)

Sizing a Scum Pipe’s Diameter

When it comes to determining the diameter of the scum pipe the main factor is the change in water elevation in the basin throughout the day. If the pipe is too small you would not be able to rotate it more than few degrees, if at all, without water entering the pipe when it rises to its highest elevation at some point during the day. Adequate diameter is needed to allow flexibility to rotate the pipe from 25 to 75 degrees, without water entering the pipe any time during its daily fluctuation in level. When the pipe is in the neutral position (with the middle of the slot positioned at 12 o’clock) you obviously do not want water to enter the pipe. That said, the bottom of the slot, when in the neutral position, must always be higher than the maximum water level in the basin. Although a conservative design is practical and common, if the pipe is too large you will be paying for more capacity than is needed. Another factor for deciding upon a scum pipe’s diameter is to consider the plant’s general rate of scum generation. This is a design consideration because if the scum quantity is high and the pipe is too small, it may not have adequate carrying capacity to convey the scum.

It is important to work with your Scum Pipe technical consultant and supply adequate information on the systems characteristics (shown above) so that they may make a solid recommendation on pipe sizing. Providing your individual system variables early in the process will result in the right equipment, in the most time effective manner possible.

Jim Brettman has been with JMS for 9 years and serves on the sales side of the business as a Sr. Application Engineer focusing on the JMS Delta-SEPARATION. He has a BS in Civil Engineering from the University of Tennessee and worked in various positions with Exxon Co. for 12 years. After locating to Charlotte, Jim ran his own business for seven years as a rep for industrial wastewater treatment equipment and systems. Jim is proud to have worked closely with Dave Myers in closing the largest single sale by JMS to date, the Boston Deer Island Delta-SKIMMER (scum pipe) project. Jim says, “I thoroughly enjoy working with a Company that embodies integrity, quality, and service as its mantra, and working with our Reps to increase the sales of JMS products.”