Question: Which is the best type of screw spiral to use in your live bottom bin?

Answer: The answer to this question depends on the application and your specific situation, but here are some points to help illuminate some of the benefits for both types of screw spirals in live bottom applications. Always remember to evaluate both options prior to selection to ensure that you have chosen the screw that fits best for your job and if you need any assistance with the evaluation of either option contact your supplier directly. As we look at each design aspect of a screw’s particular features it is important recognize that there are both positives and negatives to consider during selection.

We have previously covered some of the differences between shafted and shaftless screw conveyors and we encourage that you take a look at the presentation, but as a quick reference shafted screws are generally characterized by the fact that they have a pipe, tube, or solid shaft mounted at the center of the spiral which carries the torque and rotation, and the flights are then mounted on the center “shaft”. Shaftless spirals have no “shaft” and an open center hole, and all torque is carried through the spiral itself during rotation. In this article we will strictly be covering the topic of shafted and shaftless screws in live bottom applications.

- Shafted Live Bottom Screws

- Shaftless Live Bottom Screws

Shafted Live Bottom Screws

Shafted type screws are extremely versatile and there are numerous benefits that make it a very attractive option for live bottom applications. As we look at the advantages we will first begin with the materials of construction and cost. Shafted screws are manufactured differently than shaftless screws and due to the typical construction method of shafted screws we have a larger variety of materials to select from. Generally, shafted screws are constructed from plate steel for the screw flights (aka. spirals), and pipe or tubing for the center torque tube. Both plate steel and pipe/tube are materials that are readily available from most steel or pipe distributors in varying types of materials at reasonable prices. So for example, if your application requires additional corrosion resistance it is very common to see shafted screws built from T-304 or T316 stainless steel; or if perhaps you are handling a material that is very abrasive then there are several “abrasion resistant” materials available such AR235 or AR400 that we can be used for the screw flights. In short, there is an extensive array of available materials that we can build the shafted screws from which make it a cost effective option compared to shaftless screws. Conversely, the shaftless screws are manufactured using rectangular “bar” steel material which is not available in as large a variety as other types of steel products and can quickly become expensive if you require a special material. Also, we are also limited in materials we can select for shaftless spirals simply due to the difficult and demanding manufacturing process as certain steel materials do not react well to the stresses exerting during the spiral forming process. Ultimately the design that fits within the given budget is an incredibly important aspect that must be considered.

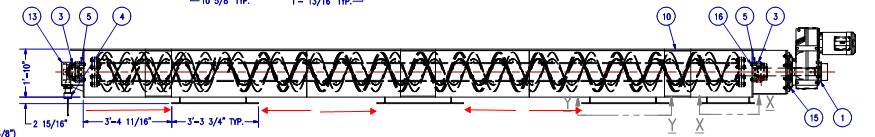

Functionally, shafted screws also present some benefits over their shaftless counterparts that make it a more attractive option in certain cases. One nice feature of shafted screws is that you have the ability to easily vary the “handing” of the screw flights from either right or left hand flighting on the same single piece of pipe. This allows us to control and move materials in multiple directions all without having to reverse the rotation of the screw (clockwise or counter-clockwise.) So in applications in which there are multiple discharge locations, with one single screw we can take materials from all points of the live bottom trough and direct them to each of the discharges without the need to stop and reverse rotation of the screw. (See ex.) This is possible with shaftless screws however use of left hand and right hand flighting on the same singular shaftless screw also requires the use of internal “hold down” bars to help maintain the correct positioning of the screw in the trough bottom. In fact, any shaftless screw requires hold down provisions when they are used in a “pushing” material orientation. Hold down provisions are an additional maintenance item to be addressed when periodically maintaining the live bottom. Additionally, with shafted screws we can alter the “pitch” (distance between flights) and outside diameter of the screw flights. This is used typically but is not limited to live bottom applications in which you need help reduce power requirements or need to help uniformly control the draw of material over the length of the live bottom opening.

Shaftless Live Bottom Screws

Shaftless screws do however have very attractive features that make it an excellent choice as well for given live bottom applications. For example, shaftless screws work exceptionally well when attempting to move difficult or problematic materials. Since there is no center “shaft” there is nothing to impede material from falling between the flighting and they are excellent at handling material with larger particle sizes. Furthermore, materials that are sticky, stringy, or can potentially build up on itself should be handled with a shaftless screw as opposed to a shafted screw. In shafted screws, sticky materials tend to build up at the connection point between shaft and flight, and stringy materials have a proclivity for wrapping around the shaft while being conveyed. In either case, both sticky and stringy materials can potentially build up in shafted screws and cause failures or maintenance trouble and shafted screws should be avoided. Shaftless screws are also not as limited in length as shafted screws are in live bottoms. It is not ideal to use screw hangers intermittently over the length of the shafted screw as the hangers become an obstruction for material flow in live bottoms and for this reason shafted screws are ideally one piece construction in live bottom applications. Thus the longer the shafted screw needs to be, the larger the center shaft will need to be to prevent mid-span deflection., and there are numerous factors that are taken into account when designing the screw, but ultimately we will eventually reach a maximum length of 30’ long. For lengths longer than 30’ long, shafted screws are no longer an option and shaftless screws are the better option.

Aside from the screws themselves we also have to consider the live bottom troughs as well because the way we design our live bottom housing is also impacted by the type of screw selected, and either option inherently has some benefits or drawbacks depending on your perspective. To begin, when we select shafted screws, we must take into consideration how they are supported and typically that is at each end of the screw. As mentioned previously, it is not ideal to use hangers intermittently over the length of the shafted screw to support the weight. For that reason, shafted screws are typically one piece construction (meaning they span the full length of live bottom trough) and are supported on each end with external bearings. On the contrary, shaftless screws are only driven at one end and the entire screw is rests on, is supported by, and rotates on a “liner” material inside the trough housing. Therefore, while the shafted screw does have external bearings which are an item that requires periodic maintenance, they are easily accessible. Shaftless screws with their trough liners require no periodic maintenance, however, will require at some point in the future a liner replacement once they are worn through which can be an undertaking depending on the size of the live bottom and the screws. The shaftless liner lifespan is generally determined by these factors; the material being handled, RPM, and the screw diameter and weight. So, as we evaluate the selection of shaftless versus shafted screws for live bottom bins we also must consider the impact to the actual live bottom bins as well.

Finding the balance to what screw fits a given live bottom application the very best is a tricky proposition and requires an understanding of both shafted and shaftless designs and all elements pertaining to each design. In the article above we have covered the most important design aspects either screw, but selecting the best also requires evaluating priorities and organizing those priorities. If you need any assistance with your evaluation and selection, Jim Myers & Sons, Inc.’s is available to help during the design process and has numerous experienced and knowledgeable team members at your disposal and we look forward to helping you with your live bottom conveyors.

Anthony Sherrill came to JMS with extensive material handling experience after spending many years with Thomas Conveyor/Martin Sprocket. He is a graduate of Texas A&M University where he studied industrial distribution, and he continues to reside in Texas. Anthony is responsible for the product management and performance of the Bio-HANDLING product portfolio globally.