Some storage vessels are meter discharged to downstream conveyors or pumps; however, a large percentage of hoppers are discharged to truck beds. They are called “Truck Outloading Hoppers”, or Systems. Live bottom screws and slide gates facilitate outloading. The hopper slide gates can be large, spanning from two up to four screw widths. No matter the slide gate size it will need an actuator. A slide gate actuator can be one of three options; hydraulic, electric, and pneumatic.

Sludge is discharged through the hopper gate by three forces: screws bringing it to the gate opening, gravity and head pressure. Thick sludge can be somewhat controlled by screw speed, however more fluid sludge (or even thicker sludge under much head pressure) can flow around the screw shaft (or thru shaftless spirals) quicker than is desired. Due to its thixotropic nature sludge varies in how fluid it is after being conveyed or pumped to hoppers. Opening a gate fully and quickly can result in a large instantaneous release and continued fast flow of sludge. This has been known to fill a truck very quickly to the point of being out of control as well as causing housekeeping issues with splatter. Being able to control hopper slide gates accurately is an important component of truck outload hopper design.

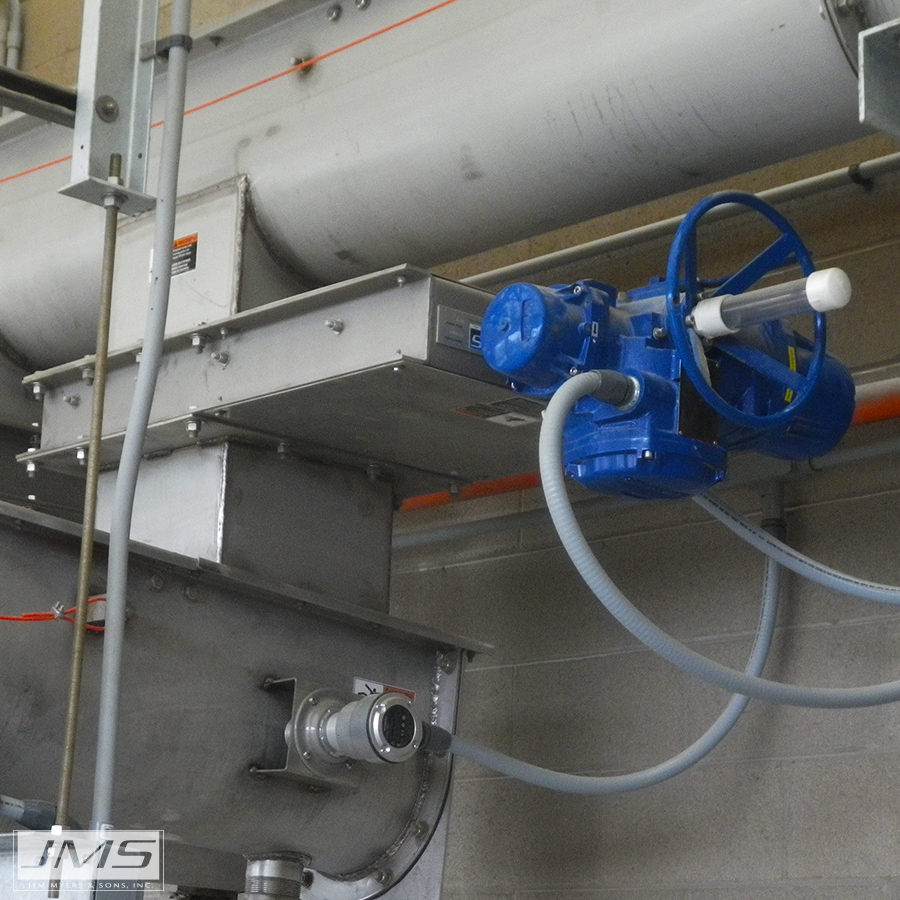

Slide Gate Actuator for Biosolids Sludge Storage:

Hydraulic Actuator

Hydraulic cylinder actuators are the best option. They are up to 10X stronger than pneumatic and can be modulated. Hydraulic fluid is nearly incompressible, so it can be accurately metered and the cylinder will move at the rate of fluid flow regardless load induced pressure (with proper control valves). Fast speed and a high degree of accurate positioning is possible. The requirement for a sophisticated and redundant Hydraulic Power Unit makes hydraulic cylinders the most expensive option.

Electric Actuator

Electric multi-turn actuators are very good. They are a bit slower than pneumatic or hydraulic but excellent at modulating and positioning. They are strong, affordable, reliable and are independent of Hydraulic Power Units or Air Compressors. The practicality of electric actuators makes them a popular choice.

Pneumatic Actuator

Pneumatic cylinder actuators are good for fully open or fully closed applications; however, they are difficult to modulate. Accurate positioning is difficult due to air compressibility, as the chamber of air in the cylinder can act like a spring. Also, because air is compressible, load-induced pressure changes will make consistent velocity difficult. Because they are relatively weak, often it takes two large cylinders in a Hopper gate app which compounds control issues.

Greg Hyde joined the JMS Sales and Marketing Team as Product Manager | Material Handling. Greg has over 30 years of experience in material handling systems, having held high level engineering, sales and business management positions with large full line conveyor manufacturers. He is responsible for overall support and growth of the JMS Bio-HANDLING product line. Outside of work, Greg is a founding member of the “Jammin’ 4 Water” (Water Charities Fundraising Inc.). In regards to his position, Greg says, “ JMS has a rich history in design, quality and material handling. I’m excited to be part of this great team and look forward to guiding the Bio-HANDLING product family for long-term growth.”