Conventional sedimentation is one of the oldest forms of water treatment. It uses gravity to separate particles from water. In order to achieve the desired results in a conventional sedimentation basin, a large basin with long residence time is needed. Results in this type of system can be affected by particle concentration, wind, sludge accumulation, temperature changes and flow rate.

Allen Hazen pioneered modern sedimentation theory in 1904 by suggesting that sedimentation is a function of basin surface area, and is independent of detention time. Decreasing settling depth can be substituted for basin length to achieve particle removal efficiency. Hence, ways to divide tanks into layers, lamella, were introduced.

Two types of lamella sedimentation equipment are currently available commercially, Tube Settlers, and Plate Settlers. Both types of equipment use shallow sedimentation theory to achieve the desired results. Use of Tube Settlers, or Plate Settlers can allow for greater loading rates of the system by expanding the surface area for sedimentation. This allows for greater loading rates, and results in a large reduction in the basin size needed to achieve the same results. It is generally accepted a reduction in settling surface area of 80+ percent can be achieved.

Tube Settlers Advantages and Disadvantages

Both Tube Settlers and Plate Settlers come with their own set of positives and negatives. Tube Settlers are manufactured by Brentwood Industries and WesTech, among others.

Tube Settlers Advantages

- They are available in blocks which can easily be fitted into many different sizes and shapes of tanks and are held in place by steel supports

- Most are manufactured from PVC so they are lightweight and economical

Tube Settlers Disadvantages

- May experience flow distribution issues with their small path for water flow, with possible plugging

- The PVC used for construction may be susceptible to breakage with chards potentially moving downstream into expensive filter/membrane equipment

- Due to their design, settling zones may interfere with incoming water

Plate Settlers Advantages and Disadvantages

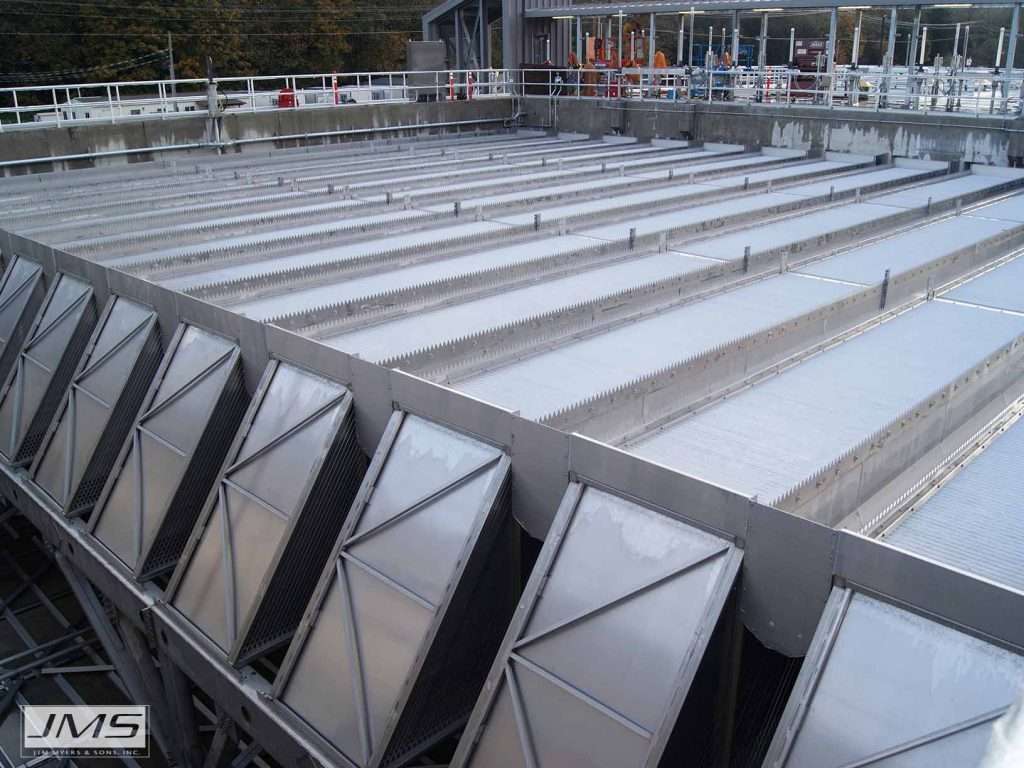

Plate Settlers manufactured by Jim Myers & Sons, Inc. (JMS), Monroe Environmental, and Meurer Research, among others, are the standard for settlement basin application in water and wastewater treatment.

Plate Settlers Advantages

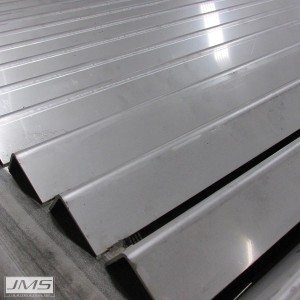

- Constructed of Stainless Steel they offer years of durability

- Low maintenance

- Longer life than Tube Settlers

- Durable plates are mounted in stainless steel frames in a modular design for easy installation at the site in new and retrofit for existing systems

- Due to their high efficiency, the size of the basin can be reduced by up to 2X compared with Tube Settlers

- Designs for wastewater treatment facilities are also offered

Plate Settlers Disadvantages

- One negative of Plate Settlers is their need for a certain installation height. This can generally be overcome by special plant specific designs provided by the manufacturer, including shorter plates to reduce the elevation.

- The initial investment for plate settlers may be greater, however this can easily be recovered due to the longer life of the stainless steel plates

JMS Inclined Plate Settler Design

Each Plate Settler manufacturer has provided their own enhancements to the Plate Settler design siting performance improvements. The JMS Mega-SETTLER (Plate Settler System) incorporates the Patented TFCA™ Top Flow Control Angle which controls headloss and clogging issues. This special design provides even laminar flow for water exiting the plates, minimizing clogging. In addition, operators can walk on top of the plates for wash-down service.

The design of the JMS Mega-SETTLER also includes Dual Side-Loaded Effluent Troughs with adjustable V-Notch Weirs that can fine tune the water elevation accommodating water fluctuations and keeping the water above the plates at the right depth to avoid an algae incubation zone and algae growth.

Choose Tube Settlers or Plate Settlers Conclusion

In choosing Tube Settlers or Plate Settlers for your specific application a number of variables including space, geometry, expected results, and life-time cost should be considered. JMS is a leader in Plate Settlers, and can use our proprietary design program, and years of experience to aid in the process. Sludge is removed from the bottom of the basin by specially designed sludge removal equipment such as the JMS hoseless Mega-VAC.

The best way to summarize this post is to look at the size comparison of a plate settler basin vs a tube settler basin. The photo below is of a water treatment plant in Bloomington, IN. This plant was upgraded due to population increase in the area. Previously the plant had a tube settler basin (see top right of the picture). The plant did not have the room for a new tube settler basin so they went with a plate settler basin. The basin performed just as well as the old sedimentation basin with only being 1/3 of the size (see bottom left of the picture).

Kerry Dissinger has been employed by JMS for the last 10 years, and currently holds the position of Vice President. Prior to receiving a BS degree in Electro Mechanical Engineering, Kerry served for 3 years as a US Army Paratrooper stationed at Fort Bragg, NC. He also served 6 years in the Pennsylvania Army National Guard. Kerry’s nearly 20 years of experience in the water and wastewater industry includes 10 years at Brentwood Industries where he was mentored by the esteemed Dr. McDowell. With his strong background in the water and wastewater process, particularly sedimentation, he is focused on continued growth and innovation, holding several active patents for JMS products. One of Kerry’s favorite sayings is: It’s not about ideas; it’s about making ideas happen.