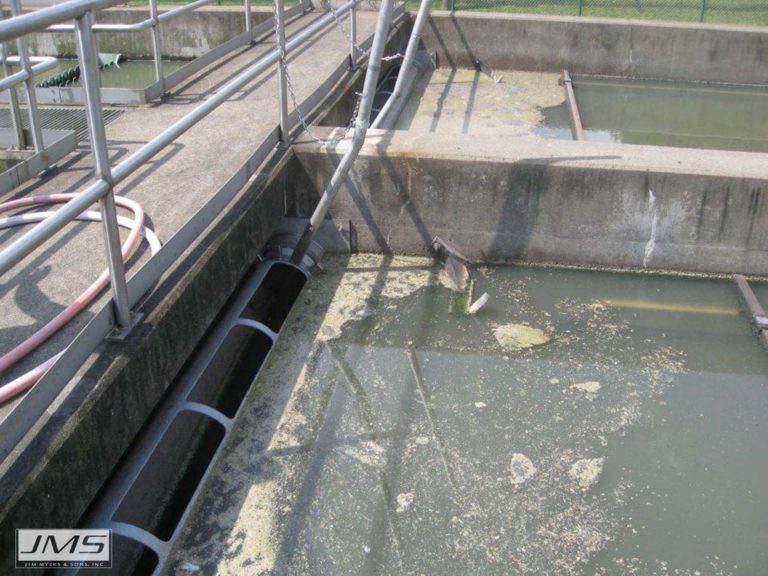

Constant or intermittent skimming and removal of floating scum from the surface of process basins is a necessity in municipal water and wastewater treatment. The most common method to accomplish this is through the use of the Scum Pipe System. Scum Pipes are manufactured by Jim Myers & Sons, Inc., Brentwood Industries, Evoqua, Polytech Systems, Walker Process, Fairfield, and Amwell, among others. Also called rotating Scum Pipes, scum skimmers, or rotating pipes or trough, these systems are employed in clarifiers, settling basins, and other process basins where surface scum is an issue.

Specifying the right equipment for the job is important. Knowledgeable equipment suppliers can be of assistance in discussing the process requirements and specifying the right materials of construction, and design for the job. In order to specify the right equipment and estimated pricing, the supplier will need to know certain information about the process.

Information needed to specify Scum Pipe System:

- Where is the project located?

- Firm quote, or budget quote?

- Number of systems?

- Diameter of pipe?

- Length required?

- What is the direction of flow, and how many open or closed end assemblies are required?

- Preferred material of construction?

- What type of operating mechanism is desired? (Lever, Worm gear, Linkage, or Chain and sprocket)

- For worm gear and linkage options, is a hand-wheel, or electric actuator operator needed? Worm gear is the most common, with chain and sprocket becoming more popular.

- If the system is electric actuated, what type of protocol is needed?

- Is the deflection criteria more stringent than the common 0.25”?

- Submittals and engineering drawings are included, are spare parts and start-up service required?

- Are wall sleeves required?

The final Scum Pipe System pricing and design is based primarily on:

- The numbers of Scum Pipes required

- Material of construction

- Desired operating mechanism.

Scum Pipe System pricing can vary widely, depending on the variables noted above. System pricing can range from $500/ft. to $2,000/ft of Scum Pipe length.

Jim Myers & Sons most commonly provides stainless steel Scum Pipes due to the durability versus FRP, and the small cost differential between stainless and painted steel materials of construction. Stainless steel is well recognized for its low life cycle cost, corrosion resistance, and its low potential for damage. Carbon steel must be sandblasted, prime coated, and coated with finish coats.

It is important to consult with suppliers offering highly trained application engineers who will discuss your specific needs and process variables to determine the right equipment for the job. Key variables are getting the right diameter pipe for the job, the right operating mechanism, and advice on whether intermediate supports are needed. Jim Myers & Sons, Inc. had been providing Scum Pipes for decades, and with thousands of Delta-SKIMMER scum pipes in service is a leader in supplying this equipment.

Jim Brettman has been with JMS for 9 years and serves on the sales side of the business as a Sr. Application Engineer focusing on the JMS Delta-SEPARATION. He has a BS in Civil Engineering from the University of Tennessee and worked in various positions with Exxon Co. for 12 years. After locating to Charlotte, Jim ran his own business for seven years as a rep for industrial wastewater treatment equipment and systems. Jim is proud to have worked closely with Dave Myers in closing the largest single sale by JMS to date, the Boston Deer Island Delta-SKIMMER (scum pipe) project. Jim says, “I thoroughly enjoy working with a Company that embodies integrity, quality, and service as its mantra, and working with our Reps to increase the sales of JMS products.”