Screw conveyors are available in both shafted and shaftless configurations. The type of conveyor that is best for your application is determined upon the needs of your individual process. For this discussion, we will concentrate on the Shafted Screw Conveyor style and the typical shafted screw conveyor wear parts.

A shafted screw conveyor is a screw conveyor that has a solid shaft that goes through the flighting of the screw. The shaft holds the flighting off the bottom of the trough. Benefits of a shafted conveyor are that they can be of longer length, there is no need for a liner and the associated maintenance, and they can run at higher RPMs since there is no concern about liner wear.

The shafted screw conveyor is generally considered low maintenance. There are, however, some common “wear items” that may need regular, or intermittent attention. Commonly, the best indicator of wear, and parts that need to be replaced are a good visual examination of the equipment and giving a close listen for any noises that sound unusual.

Typical Shafted Screw Conveyor Wear Parts

- Head and tail bearings

- Hanger bearings

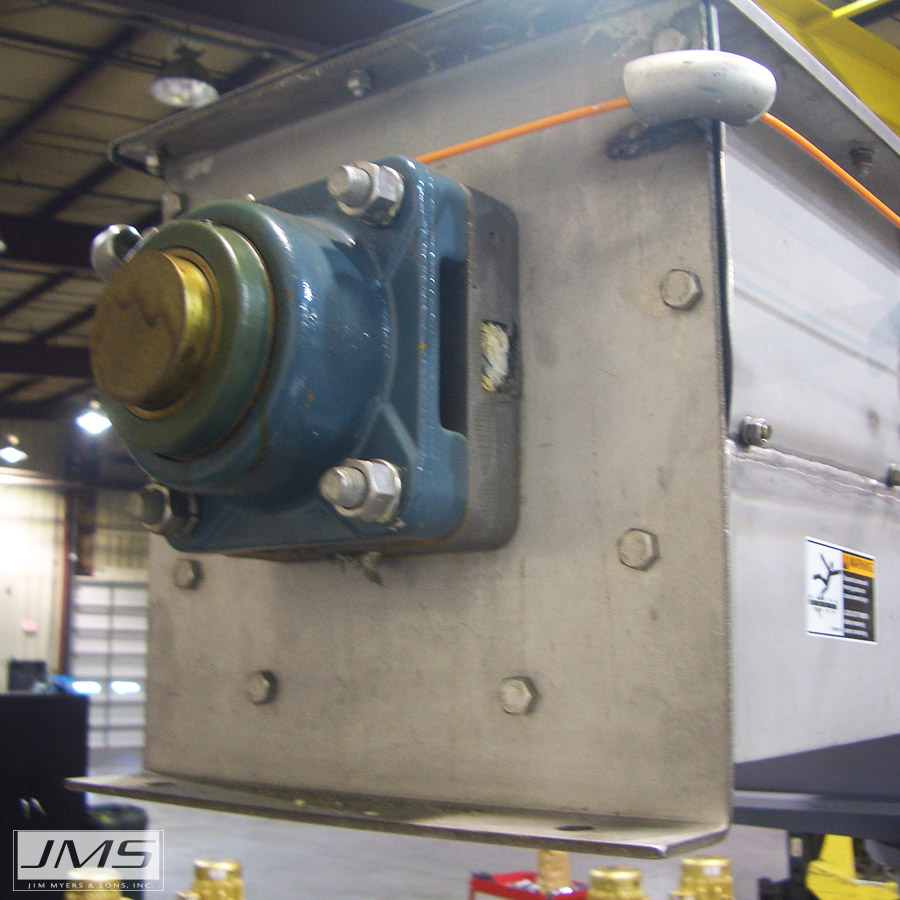

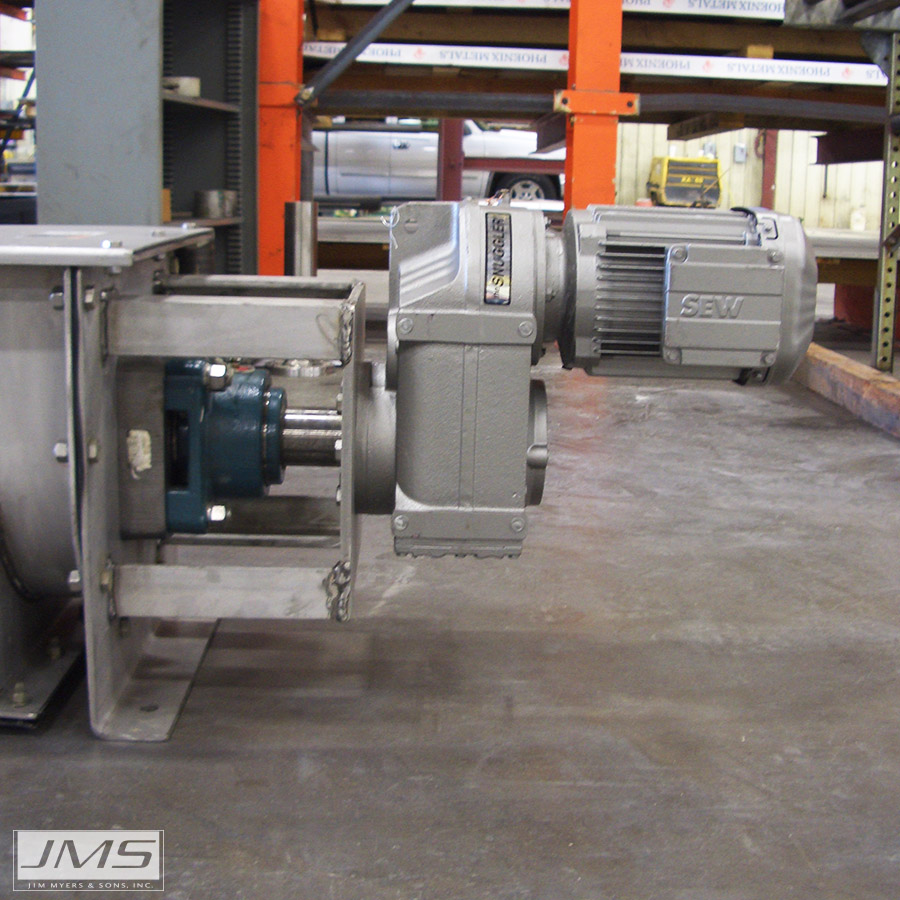

Head and tail bearings of the shafted conveyor should be watched for wear. These are on the outside of the unit at both the drive (head) and non-drive (tail) ends. Bearings should be checked for good lubrication. They have a long life, but are one of the first items that may need replacement. Indicators of this are both visual and audible.

Shafted screws have a hanger bearing every 10-12 feet. It is important to lift the cover of the conveyor and check the wear and alignment on the hanger bearings. Before lifting the cover, one should always lockout power to the unit. Bearing liners are UHMW-PE or hardened iron. Each can show wear in the long-term and can need replacement. Replacement of the hanger bearing is when wear exceeds 1/8”.

Signs of Maintenance for a Shafted Screw Conveyor

The actual screw of the shafted conveyor has a life of 5 to 10 years. The life of the screw depends on how abrasive the substrate being carried is, and amount of use. It is wise to lift the conveyor cover periodically (again, make sure the power is locked out before opening the cover) and check the screw for cracks in the flights, any reduction of the outer diameter, bent or deformed flights or material build-up.

Another indicator of need for maintenance is an overload in amperage pulled by the motor, or an overload switch that unexpectedly “trips”.

Lead times can vary for shafted screw conveyor parts with bearings being a relatively quick delivery, and a replacement screw taking much longer. It may be wise to keep some parts on hand to keep your shafted screw conveyor operating in good shape.

Troy has been with JMS for 4 years serving as an Aftermarket Parts Specialist. Having performed field service startups and repair services on new and existing equipment has given him experience with all types of JMS equipment, including flocculators, material handling, and actuators. Prior to coming to JMS, Troy was a warehouse manager and inside salesperson for a company supplying Hydraulic, Pneumatic & Power Transmission Components.